If you are considering investing in a metal 3D printer, you are likely curious about the cost. Are the machines expensive? Do they cost a lot to operate? This guide will answer all those questions and more! Keep reading to learn about the things you need to consider before buying a metal 3D printer and some of the best options on the market today.

How Much Does a Metal 3D Printer Cost?

Metal 3D printers are used for a wide variety of manufacturing needs. They are becoming faster and easier to use. These machines are powerful too since they can now use more metals than ever.

3D printing with metal has many applications for engineers, whether you are in the automotive, health, aerospace, or other industry. You can use them to build detailed parts, prototypes, and pieces that can take your business to the next level.

So, how much does a metal 3D printer cost?

Unfortunately, there is no easy answer to this question. The manufacturers of metal 3D printers don’t broadcast their prices online, so you can’t just google what the cost is. Part of the reason they do this is that they will tailor their quotes to fit the specific needs of their clients.

That means you will not be able to just order them online. You will likely need to reach out to the manufacturer, schedule some meetings, and sign a formal contract.

Even though the cost of this technology has decreased over time, it is still expensive compared to other 3D printing options. You can expect to spend anywhere from $80,000 to $1,000,000 on a metal 3D printer!

The cost will vary based on the type of metal printer you choose, as well as its size and expected performance. You will also need to add in the cost of the materials and additional tools required to complete the metal 3D printing process.

Similarly, 3D printing metal is not something anyone can do – you will need someone with serious skill and experience to operate them. We will get into this additional expense in the next section.

Things to Consider Before 3D Printing Metal

As we mentioned, there is a lot more to getting a metal 3D printer than the cost of the machine. That is only just a fraction of the cost, representing only about 40% of the total expenses associated with 3D printing metal.

You may be wondering what else you need to consider.

The total costs of ownership also includes material expenses, post-processing requirements, and operation and maintenance. Let’s get into these in a bit more detail:

Material Costs

Before you can 3D print metal, you must first buy the materials needed to make the machine work! The type of metal and materials you need will vary based on the specific machine you purchase, but this will be a recurring expense.

Most metal printers use a powder that is heated to create the metal object, and a kilogram of this can cost you anywhere from $300 to $600.

If you are working with an SLM or DMLS 3D printer though, you can expect the materials to cost $2,000 to $4,000 per build. Note that this assumes that you can fit up to 12 parts on one single build plate.

The material costs you will incur will depend on what you plan to use the 3D printer for, but make sure you incorporate this into your calculations ahead of time!

Post-Processing

Printing the metal part or prototype is only the beginning of the 3D printing process. You will need to complete post-processing steps afterward, which include cleaning the object, coating its surface, and removing support structures.

How you manage this depends on the type of machine you purchase. If you opt for a metal binder machine, you must heat the objects in an oven for sintering. Power bed fusion involves building support structures to anchor the part to the build plate, so you must remove them once it’s complete.

Here are some standard cost estimates for post-processing techniques:

- Stress Relief: $500 to $600 per build

- Heat Treatment: $500 to $2,000 per build

- Support Removal: $100 to $200 per part

- Surface Treatment: $200 to $500 per part

- CNC Machining: $500 to $2,000 per part

Like our material cost estimates, these ranges assume you can fit between six and twelve parts on the build plate.

Operation & Maintenance

Finally, you must consider the cost of operating and maintaining the metal 3D printer. Simply put, these machines are not plug-and-play. They require extensive setup and skill to operate, so you will need to hire someone to manage the machine.

That means if you plan on running the printer full-time, you’ve got to hire a full-time operator. As you can see, the expense of operating a metal 3D printer can add up quickly!

Asaf H

Head of Production Site

"Excellent experience, best platform for manufacturing"

Jiga is the best way to get the parts you need, when you need them.

Metal 3D Printing Services

There are various types of metal 3D printing services, and the cost will vary considerably depending on the technology you choose. If you need to connect with reliable and competitive metal 3D printing services, you can easily do so using Jiga’s platform.

The most common options are metal powder bed fusion, direct energy deposition, metal filament extrusion, and binder jetting. Let’s dive into how each of these processes works and what materials they use to build 3D metal objects!

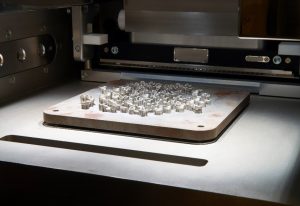

Metal Powder Bed Fusion 3D Printing

Metal powder bed fusion is the most popular choice for metal 3D printing.

SLS stands for selective laser sintering. This process relies on a high-powered laser to sinter metal powder into a solid structure.

First, the machine will dispense a thin layer of metal powder on the build platform. The machine will heat the powder to just below the melting point, so the laser can easily trace the model into a solid part.

The particles fuse layer by layer, and eventually, you are left with your completed prototype! Any leftover powder supports the structure as it is built and can be reused for future projects. Once the structure is finished, it will cool down within the machine to prevent warping and optimize its mechanical properties.

Naturally, post-processing is required. You must clean the excess powder off the part and separate the part. If necessary, you can use media tumbling or blasting to process the piece even further.

Other names for this process are direct metal laser sintering (DMLS) or selective laser melting (SLM). Regardless of what you choose to call it, this powder bed fusion technique uses lasers to selectively bond the metal particles – one layer at a time.

The average cost of an SLS or SLM printer is $550,000, but the price can climb up to $2,000,000 depending on the features you choose to include!

Directed Energy Deposition (DED)

Another type of metal 3D printing process is directed energy deposition or DED.

This method can be compared to filament extrusion since the metal powders are pushed through a special nozzle. You can also use metal in wire form, as that can also be easily pushed through the nozzle.

However, unlike SLS that sinters the material on the print bed, DED uses a laser to solidify the material as it is deposited. The robotic arm that lays the material down on the print bed also holds a laser that melts it simultaneously.

Not only does this speed up the 3D printing process, but it also reduces any material waste that you might experience with SLS machines.

The entire process also occurs in a sealed chamber because it must be filled with inert gas to prevent unwanted oxidation and to maximize control of the materials.

DED machines are perfect for repairing parts or building large 3D metal objects. Similarly, the high printing speed makes it ideal for manufacturing parts at production volumes. The drawback, though, is that you sacrifice surface quality and finish.

Most DED machines cost upwards of $500,000, so it is not necessarily a cheap option!

Metal Filament Extrusion

You can also choose a metal 3D printer that uses filament extrusion. The metal material, or filament, is heated up and processed through the nozzle.

Unlike the hazardous metal powder used in the previous options, this filament is made of metal particles mixed with a binding agent. That means it can be handled easily and safely but requires additional post-processing steps.

For example, it must go through de-binding and sintering to reach the final form.

These machines usually cost about $140,000, and this estimate includes the tools needed for post-processing. Like with all options, though, the cost can creep much higher if you select a larger, more sophisticated machine.

Material Jetting or Binder Jetting

The last type of metal 3D printers we want to mention use a material or binder jetting process.

Think of these machines like an inkjet printer – they spray the metal onto the build surface, and as soon as it hardens, another layer of metal “ink” is added onto it. Binder jetting works the same way, except that a liquid binder is also applied to the metal materials. It works layer by layer, until the process is completed.

Similarly, the prototype you construct will be very fragile until you complete the post-processing requirements. The sintering and infiltration steps will take it from its green state and turn it into a strengthened metal part.

Due to the unique technology used in this process, you can use other materials than just metal. It’s a great option if you are interested in working with sand or ceramics!

Expect to spend about $400,000 – or more – for a metal binder jetting system.

Cost of Metal 3D Printers

Now that you understand how 3D metal printing works and the different methods you can choose from, let’s review some of the best solutions on the market. This section will cover the specs for each machine as well as their average cost.

Markforged Metal X

If you are looking for an affordable metal 3D printing machine, consider the Metal X by Markforged. This option has a build volume of 300 x 200 x 180 mm and costs just under $100,000.

The Metal X’s build volume is rather large given the price. And while $100,000 is by no means cheap, it will cost you less than the other options on this list!

Please note that this cost only includes the 3D printing part of the machine. You will need to purchase a de-binding fluid wash station and sintering furnace separately. This will likely bring your total cost of ownership closer to $165,000.

It uses atomic diffusion additive manufacturing to construct metal prototypes and aims to provide a more cost-effective solution for the average consumer. The Metal X operates like an FDM printer since it uses an extruder to make metal parts from powder mixed in a plastic matrix.

When you choose this model, you can work with various steels, titanium, copper, and Inconel filaments.

3D Systems DMP FLEX 100

The 3D Systems DMP Flex 100 is a powder bed fusion machine built for industrial use. This manufacturer is very popular for metal 3D printing and is based out of the US. For users needing to build small or complex metal parts, this is the perfect solution.

The DMP Flex 100 is fast and precise, so you can quickly build the same part repeatedly. When you purchase this system, you also get access to an all-inclusive software solution that gives you everything you need to be successful with metal 3D printing.

It has a build volume of 100 x 100 x 90 mm and costs about $250,000.

Desktop Metal Studio

The next metal 3D printer on our list is the Desktop Metal Studio. This is an office-friendly option and an ideal prototyping solution.

This printer costs about $60,000. You will need to purchase the de-binder and furnace separately, and you can expect to pay $15,000 and $85,000 for these, respectively. That puts you at a total average cost of $160,000.

Even though it is a smaller model, it has a large build volume of 300 x 200 x 200 mm. It uses bound metal deposition technology to extrude unique metal rods. The de-binder will dissolve the object after it is printed, so you are left with a porous piece that must be put into the furnace.

Once in the furnace, the prototype is heated and sintered to meet the desired density and strength.

Arcam Spectra H

Another great option is the Arcam Spectra H. GE additive owns this Swedish manufacturer, and they develop 3D printers specifically for the aerospace industry.

Although the price is not on their website, we estimate that it retails somewhere between $100,000 and $250,000. It relies on electron beam melting technology, or EBM, to create lightweight and precise metal pieces.

It offers one of the largest build chambers on the market, with a height of 430 mm and a diameter of 250 mm. After the machine prints your prototype, you must move it into a powder recovery system.

Here, a magnetic separator and compressed air clean the part. The cost of this additional equipment is unknown but will likely require a significant investment.

Trumpf TruPrint 1000

The Trumpf TruPrint 1000 is a selective laser melting (SLM) metal 3D printer. It costs over $250,000, and the price will vary depending on the options you select.

This tool is an industrial machine with a large build plate of 100 x 100 x 100 mm. Since it uses metal powder as feed material, you will need to factor those costs in as well.

Even though it has a considerable build volume, the machine itself is compact. You can use it for making small prototypes and parts. Additionally, you can control it remotely through a tablet application.

EOS M 100

The EOS M 100 is an entry-level model that is priced at $350,000. This number does not include post-processing add-ons, but this machine can produce high-quality and cost-effective prints.

The EOS M 100 is powered by DMLS or direct metal laser sintering. If you need to run small batches for medical accessories or other tools, this machine will be a great fit.

It has a smaller build chamber of 95 x 100 mm, which works so well for small production runs.

Alan B.

Mechanical Engineer

"Hands-Down the Best Platform and Partner for Fast, Quality Parts"

Jiga is the best way to get the parts you need, when you need them.

Is It Worth it to Buy a 3D Metal Printer?

So, is it worth it to buy a 3D metal printer?

That depends on what your goals are. We strongly recommend that you do your research, survey your peers to see what is working for them and weigh your options.

Printing metal 3D parts can help you bring complex designs to life and support on-demand production. In other words, it improves your flexibility and control on the production line. Similarly, metal 3D printing produces less waste than CNC milling processes, thus increasing its cost-effectiveness over time.

The obvious drawback of 3D metal printers is the high cost of entry. It may take you a significant amount of time to get a positive return on investment, so make sure to calculate your throughput to determine that value.

The printing process is not perfect either and almost always requires post-processing steps. Whether it’s sintering or de-binding, you will always have to add some finishing touches to achieve the desired product.

Only you can determine if buying a metal 3D printer is worth it. Consider the pros and cons we posed as well as the unique situation your business is in!

What Is Metal 3D Printing: All You Need To Know For 2021

3D metal printing is changing the way parts are made for those in the manufacturing

Types of Metal: Classification & Application Guide

Types of metals are aluminum, stainless steel, brass, copper, bronze, and titanium. There are different

7 Tips On How To Source Quality Suppliers For Your Manufacturing Needs

The right manufacturing supplier needs to be reputable, stable, reliable, and genuinely capable of supplying