Minimum lead time

Price range

Tolerances

Layer Height

Wall Thickness

Max. Part Size

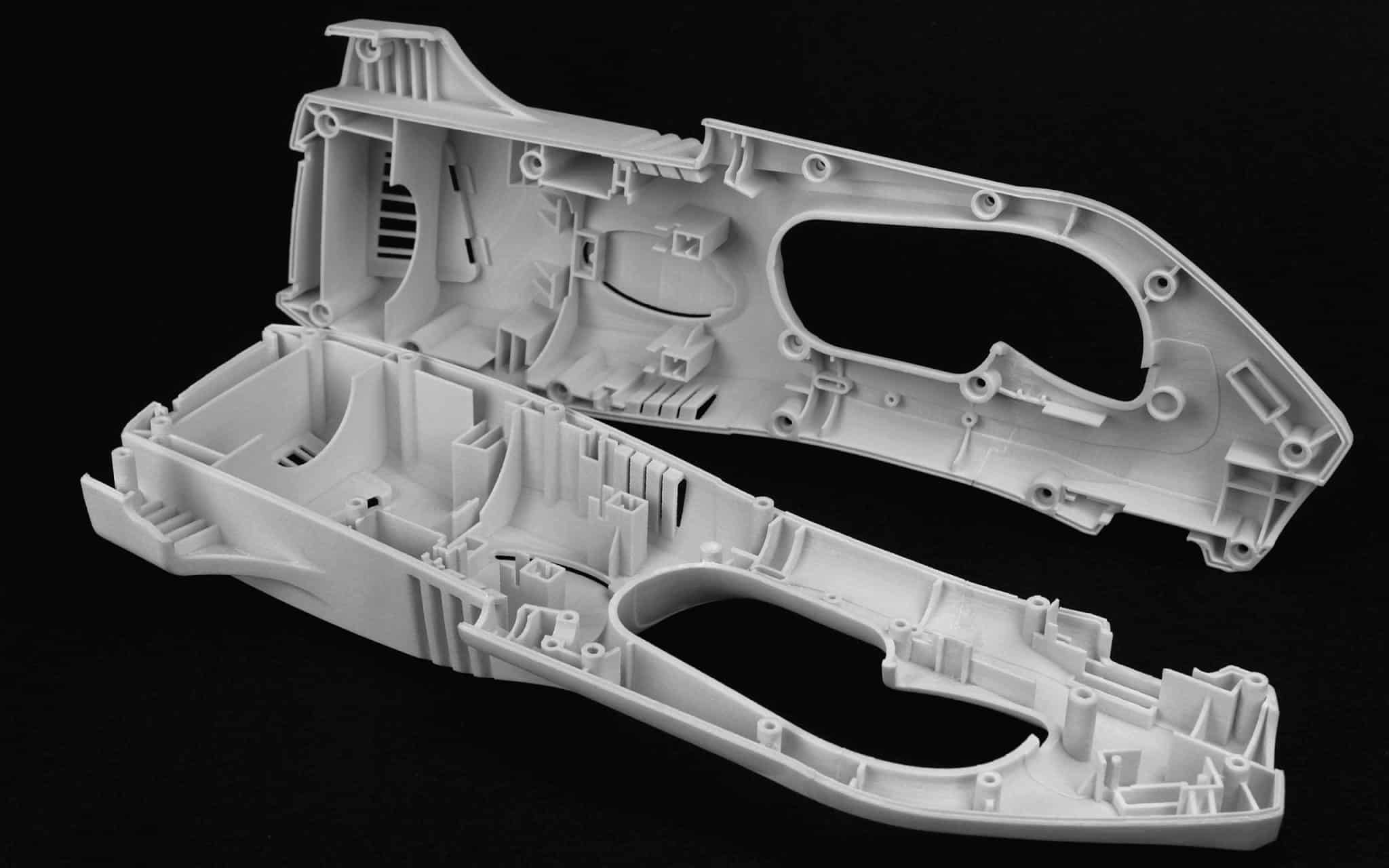

There are several benefits of using SLS as your 3D printing technology. First, it doesn't require any material to support it. Another is that SLS printed products have superb mechanical properties. Also, it can be more efficient than FDM. Lastly, it can also be used in the production of complex geometries.

The major drawbacks of SLS is that it has longer lead times and is more expensive than FDM ( Fused Deposition Modeling). Another disadvantage is that there is always a limited supply for this material. And lastly, surface finish of the part or product is rough, and there is no option of transparent or colorless material for SLS.

Carbon fiber is typically used to reinforce parts that replace machined aluminum. It is widely used in industries such as automotive and aerospace, but it is also used in sporting goods, civil engineering, and electronic fields.

"The people behind SLS or selective laser sintering were Dr. Carl Deckard and Dr. Joe Beaman. Together, they developed SLS in mid-1980s. SLS is not a standalone method in 3D printing just like other 3D printing techonologies. It uses a high-powered laser or UV laser to ""sinter"" or make a powdered plastic material solid; this is its additive manufacturing method. Since then, the same thing has been developed and modified to work with other materials such as ceramics, glass, and metals.

PBF or powder bed fusion is a collection of additive manufacturing processes. It doesn't only consist of SLS but also DMLS (Direct metal Laser Sintering) and SLM (Selective Laser Melting). "

© 2024 Jiga, Inc. All Rights Reserved.