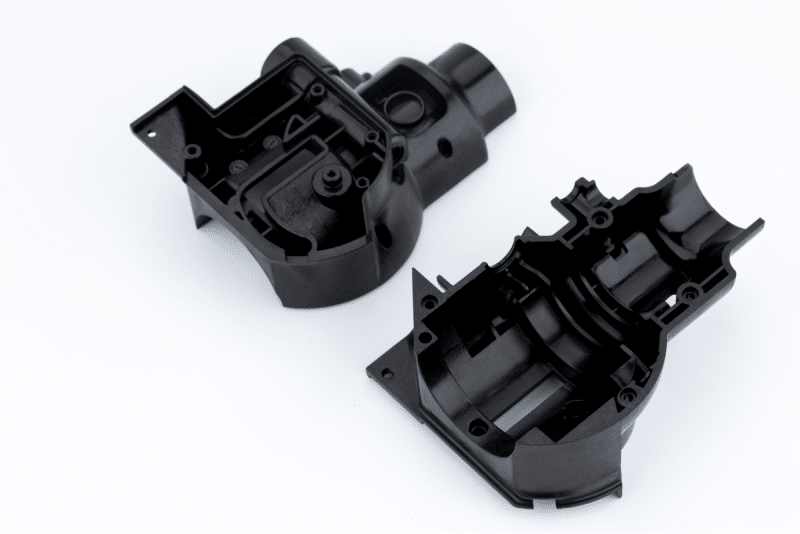

Our global network delivers precise and efficient production of custom injection molded components, meeting your specific requirements with exceptional quality

Trusted by the world’s top-tier companies

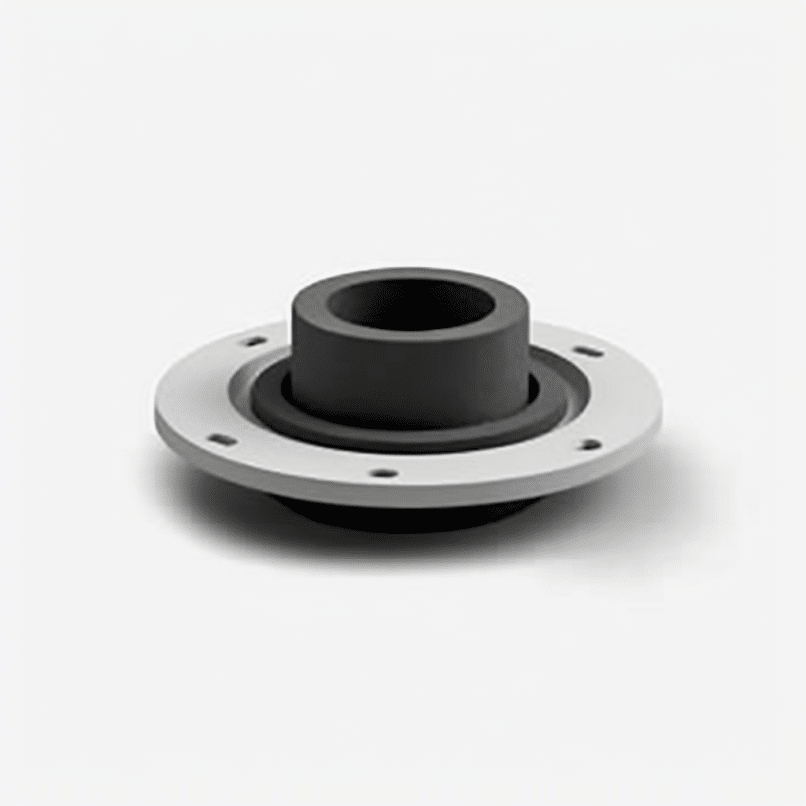

Enhance both functionality and aesthetic appeal by using rubber or silicone over existing plastic components.

Jiga supports a wide range of materials, including unique materials.

And more…

And more…

The quality and on-time delivery of your parts is guaranteed by Jiga. Jiga is ISO 9001:2015 and ISO/IEC 90003 certified. Our partners are AS 9100D and ISO 13485:2016 certified with ITAR & EAR options on demand.

Jerry S.

Mechanical Engineer

Alan B.

Mechanical Engineer

Javier L

Principal Systems R&D Mechanical Engineer

Tony K

Senior Mechanical Engineer

Shaked S

Purchasing Manager

George B

CTO

© 2024 Jiga, Inc. All Rights Reserved.