FDM 3D printers are a popular option for beginners and professionals alike. These machines tend to rely on certain types thermoplastic materials. In this article we will figure out which one is better to use: PLA vs ABS? We will go over each of their properties, uses, pros, and cons so you can make the right decision.

What are PLA Filaments?

PLA stands for Polylactic Acid. It is considered as a bioplastic made from renewable sources like sugarcane and corn starch. This sets it apart from other thermoplastics filaments. It has become one of the most popular biodegradable filaments for beginners, not to mention it’s low price point, ease of use, and availability in a variety of types and colors.

Let’s review some of the properties of PLA.

Properties

The mechanical properties of PLA are very similar to other polymers like polyurethane, polypropylene, and polystyrene. Objects made with PLA have significant tensile strength to stiffness ratio.

The required temperature to melt and fuse PLA is relatively low. The glass transition temperature of PLA is about 55 degrees Celsius, and the material will melt at 180 degrees Celsius. Note that PLA is flammable, so you should take appropriate precautions when 3D printing with this filament.

Since PLA comes from more eco-friendly substances, it can biodegrade. On average, it will take about 50 days for it to break down in an industrial composter – and up to 48 months in water. On the bright side, it doesn’t produce odor during printing, so you can use it comfortably in an indoor environment.

Uses

So, what is PLA normally used for?

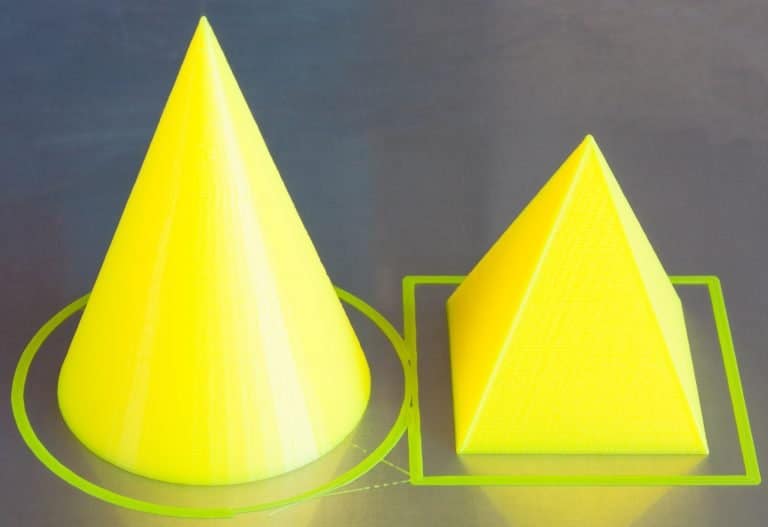

Most businesses use PLA for building prototypes since it allows you to create complex and detailed models fast. The variety of choices in colors and types also adds value. That makes it the perfect option for demonstrating the aesthetic and visual properties of your prototype. It’s low cost, which means that you can visually analyze several designs without burning through money and materials.

However, since PLA is biodegradable, it has a shorter lifespan, poor water resistance, and solvency. In other words, it’s useful for aesthetic uses, concept models and mockups, but not for the real thing.

There are other applications for PLA besides prototypes, though!

In the world of manufacturing, PLA is generally recognized as safe for food, it is commonly used in the food-packing industry. However, when it comes to the printing industry, it is more difficult to produce food-safe items since it could be contaminated throughout the production process.

For some hobbyists, PLA is perfect for printing customized gifts for display.

There’s a reason that PLA has close to 45% of the market share for creating 3D objects! Unfortunately, no material is perfect, and that includes PLA. In the following sections, we’ll talk about the pros and cons of this filament.

Javier L

Principal Systems R&D Mechanical Engineer

"Game changing in the online manufacturing space"

Jiga is the best way to get the parts you need, when you need them.

Pros

- Biodegradable – although this is an intriguing subject in the industry, the fact that it comes from renewable materials makes it an attractive choice since it has a reduced carbon footprint. You can compost PLA, and there are fewer fumes emitted when you burn the material.

- Low-cost – as mentioned, compared to most filaments, PLA has a lower price point. Making it perfect for practicing your printing skills without worrying about how much you’ve already spent.

- Versatile – PLA requires less energy to manipulate. It doesn’t need a heated bed and easily melts in low temperatures. Thus making it a default choice for beginners. This feature also makes it inexpensive and extremely easy to print with, which are some of the top considerations when choosing a filament for 3D printing.

- Aesthetically pleasing – this filament comes in so many different colors, types, and transparency choices . Post-processing using sanding and trimming is also easier to make the end product smoother and shinier. It is a popular choice for rapid prototyping that requires more rigid and detailed prints.

- Odorless – that basically explains it. Since it is plant-based, printing with PLA won’t hurt your nose or anyone else’s.

Cons

- Environmental Impact – even though it is considered a more environmentally friendly option, it does not mean it won’t impact nature. Intensive farming practices can lead to the destruction of natural habitats – and plants and crops are used to create this thermoplastic.

- Low heat resistance – The low melting point of PLA also means that you can’t recycle it with other plastics, which poses additional hurdles for sustainability. This drawback also applies to environments with high temperatures since objects made from PLA can start deforming or softening during a hot summer day!

- Permeability – another con for PLA is that it is more permeable than other thermoplastics. As a result, oxygen and moisture can pass through it with ease.

- Low durability – this type of filament is not the strongest plastic either. If you need an object with high impact resistance and toughness, PLA will likely not work. It is less sturdy and more brittle.

What is ABS Material?

Now that you know the basics of PLA, let’s move on to another type of filament: ABS.

ABS, or Acrylonitrile Butadiene Styrene, is a thermoplastic that became popular for its applications in the injection molding industry. ABS is constructed from monomers that are derived from petroleum, and each one plays a role.

For instance, butadiene gives it rubber-like properties that enhance the rigidity provided by styrene alone. Acrylonitrile, on the other hand, allows it to have heat stability and chemical resistance.

Properties

ABS is a technical filament used for more challenging 3D printing needs. The products produced with ABS are stiff and can easily resist heat and impacts, making them very durable and effective.

If you need a 3D printing filament that comes in flame-retardant and palatable grades, consider ABS. The yield strength will vary based on the grade you choose, but all levels are sturdy and tough.

It has a relatively low melting point of 200 degrees Celsius. Likewise, ABS can melt and cool down without exhibiting any changes to its chemical properties, which makes it a unique 3D printing filament.

Products made from ABS also have high-quality finished – when handled properly, of course – which is another appealing property.

Uses

At this point, you may be wondering, what is ABS filament used for in 3D printing?

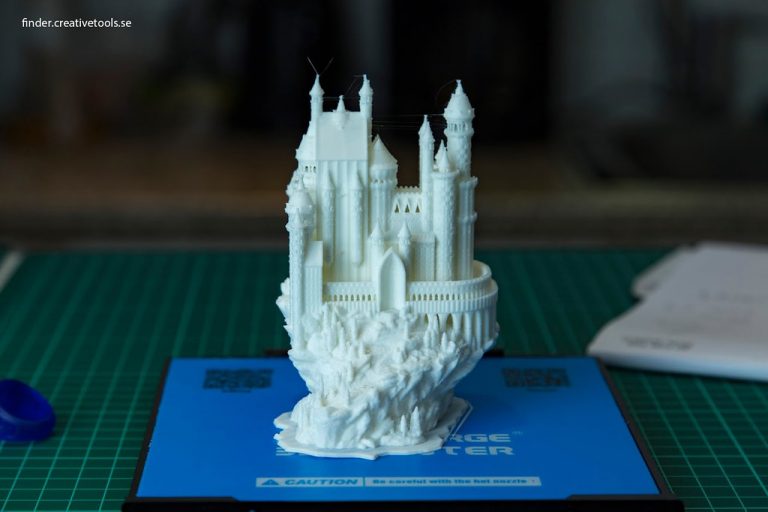

Since ABS is such a versatile material, there are a wide variety of applications. For example, it can make everything from auto parts and electronic housings to Legos! You can even use it for making computer monitors and TVs.

ABS can create objects that use moving parts or tools that need to withstand high mechanical stress. In other words, ABS has engineering and manufacturing applications for things like protective cases or 3D printer parts.

If your prototypes need to be functional, ABS is an ideal solution. It is durable enough to create an end-use product but detailed enough to show you everything you need to visualize.

Pros

- Good mechanical properties – ABS is very stiff, hard and sturdy. It’s a bit more flexible than other options, so you can bend it further before it breaks. The material does well with machining and provides good dimensional stability. Thus makes it a perfect choice for printing tool parts that need superior strength and durability like machine parts. It is highly resistant to heat, electricity, and other chemicals. It’s advisable to be used for prints that will need to endure heat up to 60ºC.

- Post-process friendly – when you create objects that require extensive post-processing, ABS filament is going to be your best option. It can easily be glued, sanded down, and filed, and it is soluble in acetone vapor. That means you get a polished, smooth finish! It is also easy to glue and paint products made with ABS.

- Affordability – although ABS is an impressive material, it is also affordable. You can find a spool of this filament for as low as $15, so you will not be able to find a better value.

Cons

- For advanced users – 3D printing with ABS requires much more skill when compared to other filaments. You need skill and experience to carefully control the temperature, if not your objects will end up with split layers and cracks.

- Need for heated bed – warping and curly can also be an issue when 3D printing with ABS. You need to choose a machine that has a heated bed and enclosure since the printers without them will struggle to use this material effectively.

- Strong odor – this material also emits strong, toxic fumes during the 3D printing process. The styrene in particular results in higher emission of dangerous volatile organic compounds, or VOCs. As a result, you must choose a properly ventilated room before moving forward.

- Sensitive to UV rays – parts that are printed with ABS should not be used outdoors, since they are extremely sensitive to UV rays. Exposure to direct sunlight can cause the product to sustain damage, so if you need to use your prototype outside consider choosing another type of filament.

Jerry S.

Mechanical Engineer

"The holy grail of good speed, quality, and price for custom parts"

Jiga is the best way to get the parts you need, when you need them.

Understanding the Differences between PLA and ABS

While you have likely identified several differences between PLA and ABS already, let’s review these in greater detail.

Both filaments are thermoplastic, but PLA tends to be better for beginners or hobbyists because of its limited heat resistance. If you need to 3D print for commercial or industrial applications, ABS is often the optimal choice.

So, which is more flexible, PLA or ABS? ABS is lighter, more flexible, and stiffer. It has a higher elongation at breaking than PLA. Thus, ABS is a better choice for prints that need to be exposed to physical stress.

Similarly, whereas PLA is user-friendly and easy to 3D print with, ABS requires additional skill and experience to use. A heated print bed and an extruder that can reach higher temperatures are also needed to print out of ABS. It also needs an enclosure when printing for it to not be exposed to temperature changes which can cause warping and curling.

PLA has a lower melting temperature, so you do not need a heated print bed. Its stiffness and strength also mean that you will experience fewer warping issues during extrusion. Even though it is easier to print with, it loses a lot of its stiffness when exposed to high temperatures and can also be brittle.

Lastly, when it comes to fumes, PLA filament is generally milder than ABS since it is a bioplastic. Whilst ABS’ fumes are strong and toxic.

So, Which Material is Best for 3D Printing?

Choosing to 3D print with PLA or ABS is not always a straightforward choice. Which is best? What material should you choose?

The answer to this question depends on what you plan on using your 3D printer for. Both materials are effective and useful, but for their own reasons. They also have similar costs, so that won’t necessarily drive your decision.

If you are just starting or are looking to print detailed models that don’t necessarily require functionality, consider PLA. It focuses on aesthetics over functionality and works best for hobbyist projects.

On the other hand, consider choosing ABS filament if you need to print objects with improved machinability, strength, and thermal stability. These 3D prints are more prone to warping and require more skill to create, but they are highly functional and can withstand stressors and impacts.

As you can see, you should choose PLA or ABS according to your use case. Start by determining what your 3D printing goals are, and you can arrive at the right answer from there!

At Jiga, we work with highly qualified professionals that can help you decide which material is best suited for your needs! Explore suppliers, source, and order custom parts as you need them.