Additive manufacturing, and 3D printing, in particular, have unarguably revolutionized how we approach manufacturing. The advent of affordable commercial 3D printers has also allowed users of every scale, from tech startups to home hobbyists, unparalleled creative functionality. However, 3D food printers have yet to make their mark in the food services industry.

The toxic chemicals used in common 3D printing and finishing processes just aren’t compatible with a food-safe environment. Until now.

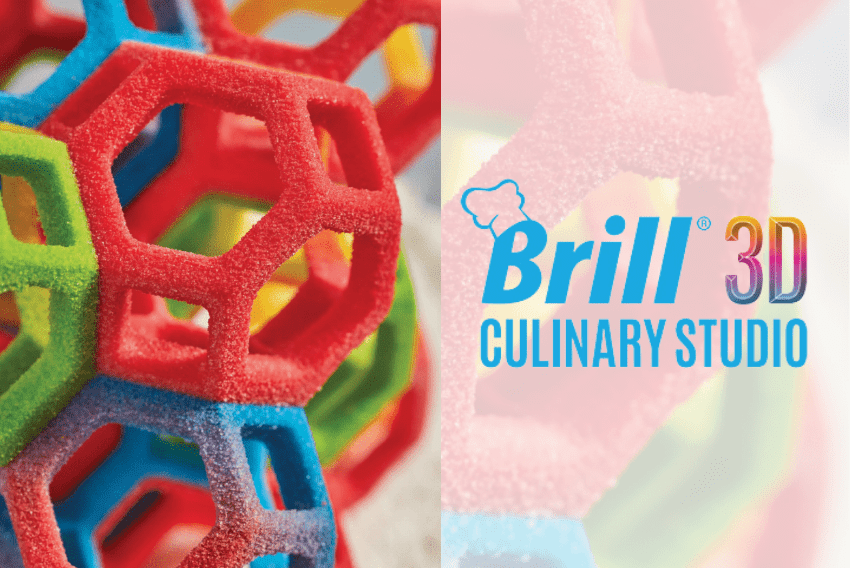

Brill, Inc, an established bakery solutions company, partnered with 3D Systems on a multi-year collaboration that resulted in the Brill 3D Culinary Studio. This 3D food printer uses powdered sugar and liquid binders to create complex sugar creations in multiple colors and flavors.

What Is 3D Food Printing?

The idea of printing 3D edible items has been around for as long as the concept of 3D printing has and this isn’t the first 3D food printer that 3D Systems has made.

In 2014, the company launched the ChefJet and the ChefJet Pro. A similar system, the ChefJet combined sugar with flavored binders to create single colour, single flavour, sugar creations.

The Pro vision was able to mix colors and flavors during the printing process.

At the time, the diminutive size of this food 3D printer and its USD$5,000 price tag, USD$10,000 for the Pro, meant it didn’t make much of an impact in the consumables industry.

Fast forward to 2020 and 3D Systems have updated their original idea using more modern 3D printing processes combined with the culinary expertise of Brill.

During 2019, the Brill 3D Culinary Studio was tested at a variety of restaurants, resorts, and casinos and the feedback incorporated into the design.

What Can the Brill 3D Culinary Studio Produce?

The primary use of the Brill 3D Culinary Studio is to produce edible sugar ornaments. Brill and 3D Systems are marketing the printer a way to “allow for the mass production of small decorations and large statement pieces in record time.”

Aimed squarely at the commercial market, the Brill 3D Culinary Studio will allow kitchens, bakeries, and other culinary outlets to produce small, inexpensive, intricate, full-color garnishes and cake toppers in bulk.

The system can print relatively quickly and, as the sales brochure notes, can be left running during non-peak times to produce these edible designs with minimal oversight.

The marketing produced by Brill and 3D Systems does show that the Brill 3D Culinary Studio can produce some highly geometrically complex, intricately patterned sugar creations.

These sugar models are ideal as edible flourishes, garnishes, cake toppings, and, in the words of Brill, “edible moments.”

The main drawbacks of the system are based mainly on the materials used. The size and dimensions of what the Brill 3D Culinary Studio can produce are restricted since sugar is not the most durable material.

Additionally, the Brill 3D Culinary Studio can only create sugar constructs, making it very suited to certain business models and less useful to others.

George B

CTO

"Hands-Down the Best Platform and Partner for Fast, Quality Parts"

Jiga is the best way to get the parts you need, when you need them.

Will We Be 3D Printing All Our Food Now?

Probably not. Although that isn’t what the Brill 3D Culinary Studio is claiming it can offer.

Brill, inc has a nearly 100-year history of providing commercial goods to bakeries and that would seem to be the area in which this printer has the most utility.

Many bakeries now offer personalized cakes and sweets for special occasions and the Brill 3D Culinary Studio offers the opportunity to simplify and streamline that process.

Rather than attempting to handcraft items out of sugar paste, bakeries can use the Brill 3D Culinary Studio to create intricate and personalized 3D designs and then print them in an edible format.

The same idea can be applied to edible cocktail garnishes, wedding cake toppers, and a huge range of other small edible decorations that the Brill 3D Culinary Studio can produce quickly without supervision.

However, if it is successful, the Brill 3D Culinary Studio could work as a proof of concept that would lead to more advanced food 3D printers.