Most of us are very familiar with ChatGPT.

This magical tool, capable of deeply understanding complex topics and instructions and performing tasks.

But fully realizing its potential use cases takes time and effort. There’s so much noise out there, and new AI apps are released every day.

For procurement and supply chain professionals, there’s one release worth noticing that’s been barely discussed. It has a pretty ugly name in my opinion, but it has some incredible potential.

It’s called ChatGPT’s Code Interpreter.

For procurement and supply chain professionals, it’s a productivity game changer. I believe that it can be one of the most useful AI use cases for professionals.

Let’s dive in.

First, A few words about data privacy

Data privacy is paramount in today’s digital age. While OpenAI’s policy states that ChatGPT does not store your files or data, it’s always crucial to be extra cautious when dealing with sensitive information. One prudent practice is to anonymize your confidential data by using code names or pseudonyms that you can later decrypt. This way, you’re adding an extra layer of protection to your sensitive procurement data, ensuring it remains secure while you extract valuable insights. Marijn Overvest from Procurement Tactics also listed mistakes to avoid when using ChatGPT in procurement. You might want to check it out first.

Why You Should Care About ChatGPT Code Interpreter

Procurement and supply chain teams spend much of their time analyzing data and managing spreadsheets or their digital platforms.

Think about it:

- Cost reduction

- Risk management

- Supplier relationships

- Inventory management

- Planning and forecasting

These are just some of the use cases requiring hours and hours of deep data analysis.

The reason that Code Interpreter has such dramatic potential is that it can run complex data analysis tasks on files, such as spreadsheets.

Now you can input files into ChatGPT and get analysis that will help with your decision-making. For only $20, you get a data analyst that can help with your procurement data analysis.

The Code Interpreter function in ChatGPT works in tandem with a data set, say a spreadsheet or a database extracted from your ERP. It reads and analyses the data, providing understandable responses to queries or generating useful reports.

Here is a list of what you can do with 3 different data sets to spark your imagination.

Jerry S.

Mechanical Engineer

"The holy grail of good speed, quality, and price for custom parts"

Jiga is the best way to get the parts you need, when you need them.

Analysis of past orders data

Let’s say you want to analyze a spreadsheet of order data. A procurement manager would typically spend countless hours sorting and analyzing this information.

But with the code interpreter feature in ChatGPT, you can analyze:

1. Supplier Performance

Evaluate how well suppliers are meeting their obligations. This could involve analyzing data such as delivery times, product quality, and accuracy of orders (how often do they deliver exactly what was ordered).

Prompt: “What is the average delivery time for each supplier? How often does each supplier deliver exactly what was ordered?”

2. Spend Analysis

Understand how much is spent with each supplier and in which categories. This can help identify areas where you might be able to negotiate better pricing or payment terms, consolidate spend with fewer suppliers for better leverage, or where it may be appropriate to diversify suppliers to reduce risk.

Prompt: “What is the total amount spent with each supplier? What is the total spend in each category of goods or services?”

3. Order Trends

Examine the patterns of ordering over time. Are there certain times of the year where orders spike? This can assist in forecasting future needs and ensuring that suppliers can meet demand.

Prompt: “Can you provide a monthly breakdown of orders for the past year? Can you highlight any significant changes in order patterns?”

4. Inventory Turnover Rates

Understanding how quickly inventory is used can help optimize inventory levels and reduce costs associated with excess inventory or stockouts.

Prompt: “What is the average inventory turnover rate? How does this rate differ across various goods or services?”

5. Pricing Trends

Keep track of how the price of goods or services has changed over time. This information can be valuable during negotiations with suppliers or when planning budgets.

Prompt: “How has the price of each good or service changed over time? Can you plot a graph illustrating these trends?”

6. Order Size

Analyzing the typical size of orders can help identify potential economies of scale (larger orders might get better pricing) or indicate where smaller, more frequent orders might reduce inventory costs.

Prompt: “What is the average order size for each supplier? Are there potential economies of scale to be leveraged?”

7. Lead Time

Understanding the usual lead time from order to delivery for each supplier can help with planning and identifying any potential issues in the supply chain.

Prompt: “What is the average lead time from order to delivery for each supplier? Are there any outliers or significant deviations?”

8. Contract Compliance

Ensure that the terms of supplier contracts (like pricing, quantities, etc.) are being adhered to.

Prompt: “Were there any instances where the actual pricing or quantities differed from the contract terms?”

9. Geographic Analysis

Understanding from where goods are being sourced can help identify potential risks (e.g., political instability, natural disasters, etc.) or opportunities (e.g., local sourcing, reducing transport costs or time).

Prompt: “Can you categorize our orders based on the geographic location of our suppliers? What are the potential risks and opportunities associated with each region?”

10. Product Quality

Tracking the rate of returns or complaints can give insights into product quality, which could lead to discussions with suppliers or possibly seeking new suppliers.

Prompt: “What is the rate of returns or complaints for each product? Are there any patterns or correlations with specific suppliers?”

Here’s an example.

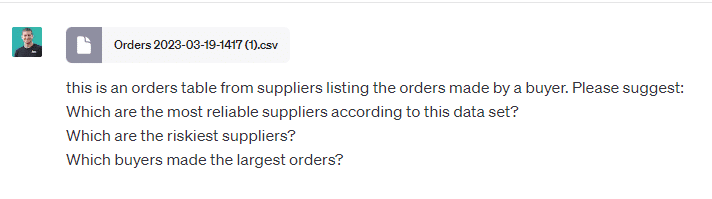

I gave ChatGPT an anonymized data set containing past orders:

Order Name, Order Number, Buyer Name, Items, Qty, Supplier, Price, Committed Delivery Date, Actual Delivery Date, Status, Flags, Est. Package Size, Est. Weight, part number.

Here’s what I asked it to do – the prompt asked about the riskiest suppliers, the most reliable suppliers and an easier question about the buyers who made the largest orders.

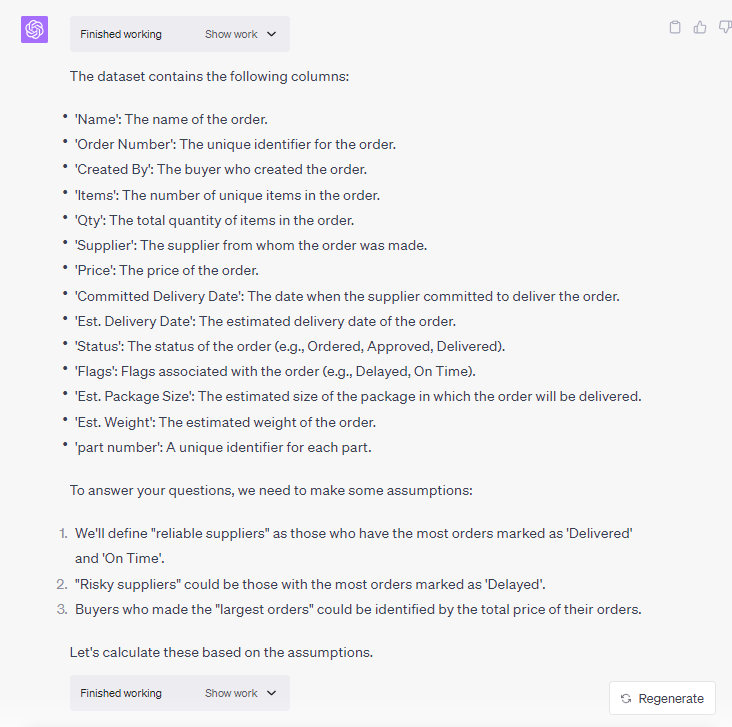

ChatGPT Code Interpreter understood my requirements and mentioned how they’ll approach the questions:

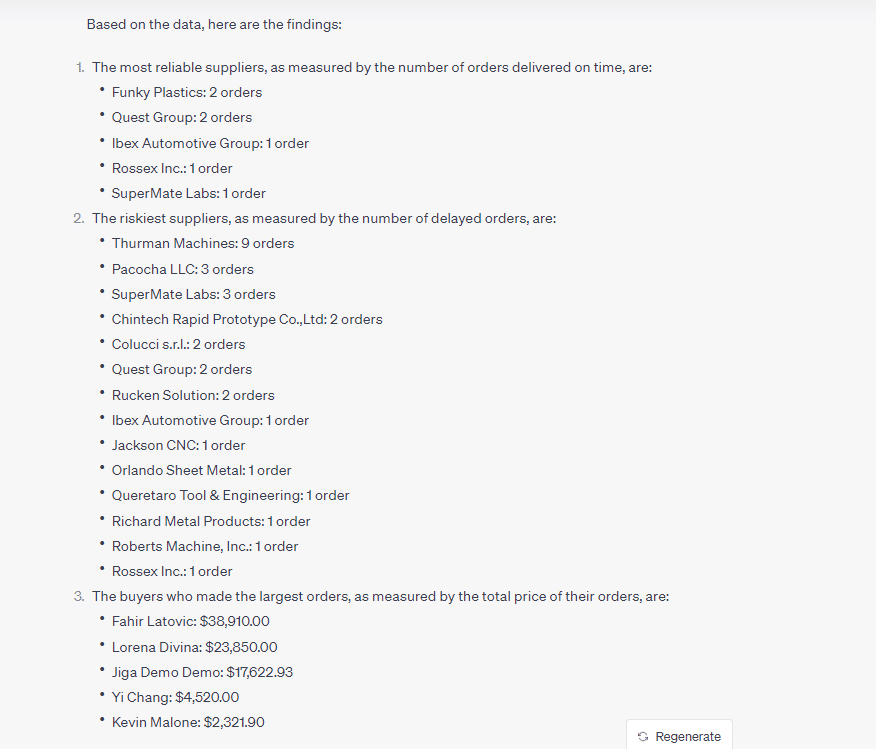

Then, it shared its analysis based on the assumptions.

Extracting information from past RFQs and responses

This time, let’s say you have a document filled with RFQ and quoting information. Procurement managers handle numerous RFQs and responses, and it becomes challenging to glean useful information from these vast data sets.

But with the code interpreter feature in ChatGPT, you can analyze things like:

1. Supplier Response Time

Assess how quickly each supplier responds to RFQs. Faster responses can indicate a supplier’s efficiency and reliability.

Prompt: “What is the average response time for each supplier to our RFQs? Are there any significant deviations?”

2. Quote Competitiveness

Compare the quotes received for similar goods or services to understand which suppliers are more competitive in pricing.

Prompt: “How do the prices quoted by each supplier compare for similar goods or services?”

3. Acceptance Rate

Analyze the ratio of quotes accepted to quotes received. This can indicate supplier reliability and competitiveness.

Prompt: “What is the acceptance rate of quotes for each supplier?”

4. Terms and Conditions

Review the terms and conditions provided by each supplier in their quote. Unfavorable terms might be a hidden cost even if the quoted price is low.

Prompt: “Can you summarize the key terms and conditions provided by each supplier in their quotes?”

5. Supplier Diversification

Check the number of RFQs sent to different suppliers. A balance needs to be struck between supplier diversification and consolidation.

Prompt: “How many different suppliers have we sent RFQs to in each category of goods or services?”

6. Delivery Time

Analyze the proposed delivery times in each quote. Faster delivery might warrant a higher price in some situations.

Prompt: “What are the proposed delivery times by each supplier in their quotes?”

7. Quote Conversion Rate

Check the rate of RFQs that end up in a purchase order. This can help identify potential issues in the RFQ process.

Prompt: “What is the conversion rate of our RFQs into purchase orders?”

8. RFQ Frequency

Review how often RFQs are sent out. This can inform about market trends and supplier performance.

Prompt: “Can you provide a breakdown of the frequency of RFQs sent out over the past year?”

9. Supplier Engagement

Identify which suppliers engage more proactively with the RFQ process. This might be indicative of their customer service and commitment.

Prompt: “Which suppliers are more engaged and responsive in the RFQ process?”

10. Historical Quote Analysis

Review the quote changes over time from each supplier. This can give insight into market trends and supplier pricing strategies.

Prompt: “How have the quotes from each supplier changed over time? Can you plot a graph showing these trends?”

Alan B.

Mechanical Engineer

"Hands-Down the Best Platform and Partner for Fast, Quality Parts"

Jiga is the best way to get the parts you need, when you need them.

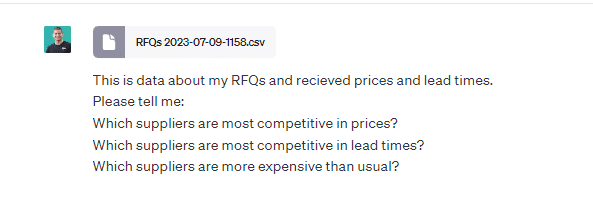

Here’s an example for that. I gave ChatGPT an anonymized CSV containing RFQs and supplier responses with prices and lead times. I asked about which suppliers are more competitive than usual, which are most competitive in price and which are most competitive in lead times.

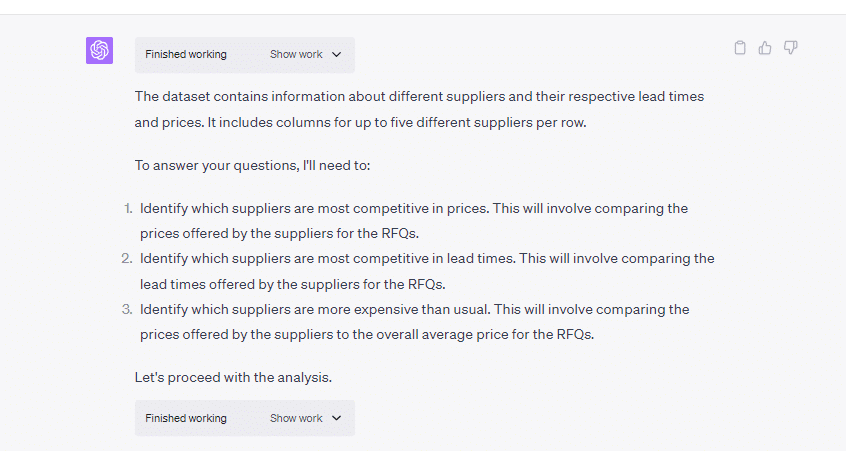

Again, ChatGPT first explained what it is going to do and its assumption when analyzing the data.

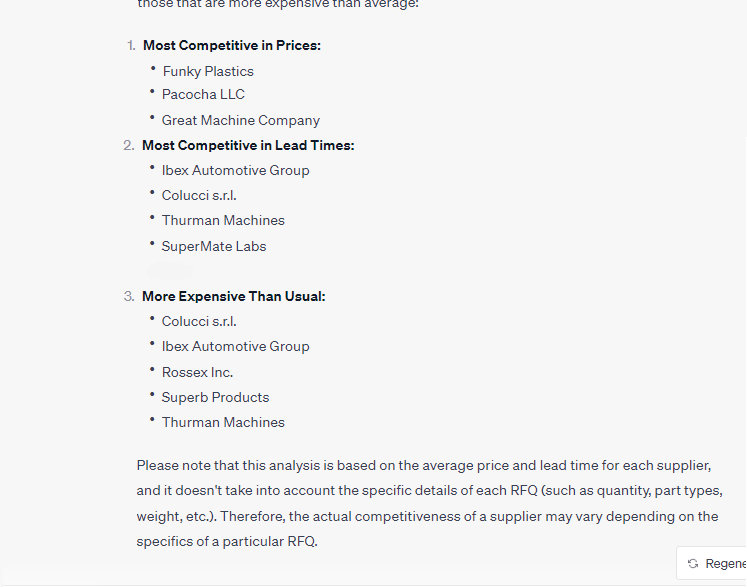

Then it gave me the analysis:

BOM data and suppliers

Now let’s do the same process with a spreadsheet containing data with your BOM and suppliers you procure your items from:

1. Component Costing

Understand the cost breakdown of each component in the BOM from each supplier.

Prompt: “What is the cost of each component in the BOM from each supplier?”

2. Supplier Contribution

Assess which suppliers provide the most components or the most critical components in your BOM.

Prompt: “Which suppliers provide the most components in our BOM? Which ones provide the most critical components?”

3. Component Availability

Understand the lead times and availability of each component from different suppliers.

Prompt: “What are the lead times and availability of each component from our suppliers?”

4. Single Source Components

Identify components that are only available from a single supplier, which can be a potential risk.

Prompt: “Are there components in our BOM that are only procured from a single supplier?”

5. Substitute Components

Determine if there are alternative components that can be used if the primary component is not available.

Prompt: “Are there alternative or substitute components listed in the BOM? What are their costs and availability?”

6. Total Cost Analysis

Calculate the total cost of each final product based on the BOM and supplier costs.

Prompt: “What is the total cost of each final product based on the BOM and the costs from each supplier?”

7. Supplier Dependence

Understand your reliance on each supplier by assessing the value or volume of components procured from them.

Prompt: “How much do we depend on each supplier in terms of the value or volume of components procured?”

8. BOM Changes Over Time

Review how the BOM has changed over time and how this has impacted costs and supplier relationships.

Prompt: “How has the BOM changed over time and how have these changes impacted costs and our relationships with suppliers?”

9. Lead Time Analysis

Calculate the total lead time to manufacture a product based on component lead times.

Prompt: “What is the total lead time to manufacture each product based on component lead times?”

10. Geographic Analysis

Identify where components are being sourced from and assess the potential risks and opportunities.

Prompt: “Where are our components being sourced from? What are the potential risks and opportunities associated with each region?”

By identifying potential risks, you can develop contingency plans, diversify your suppliers, and ensure the steady flow of materials.

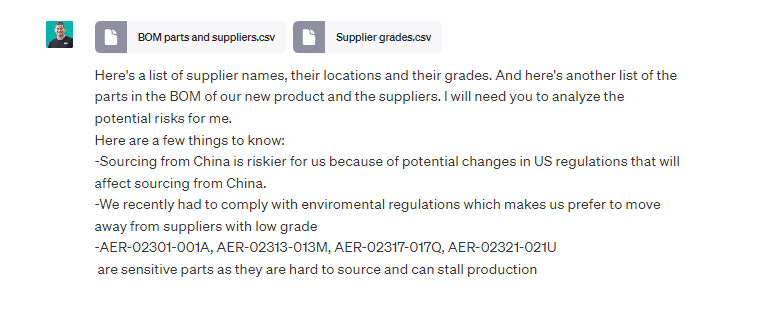

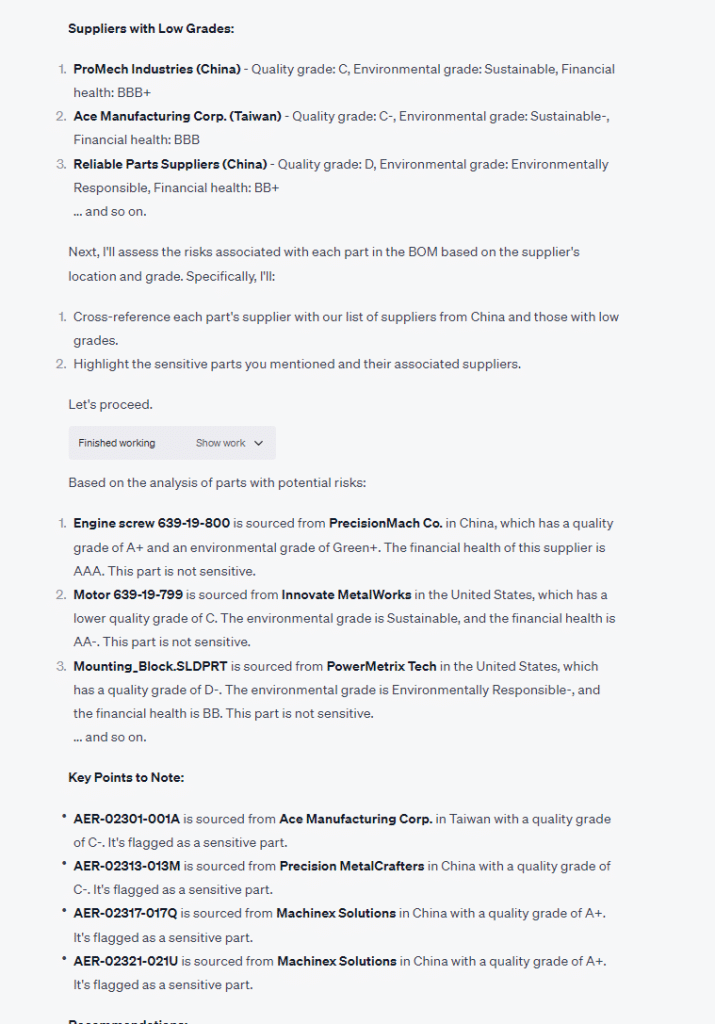

- A BOM with suppliers and alternative supplier names

- A list of suppliers and locations with with their grades in different criteria: Environmental, Quality, Financial

ChatGPT analysed the info:

And it gave me recommendations – like avoiding single sourcing for certain sensitive parts, especially those in that specific country.

Making data-driven decisions in manufacturing procurement just got easier

ChatGPT’s code interpreter holds immense potential for procurement managers in manufacturing. It’s not just a tool but a strategic partner that can guide you toward data-driven decisions and risk mitigation. Embrace this AI-powered tool to unleash a new level of efficiency in your procurement process.