Manufacturing is a critical aspect of any business, and selecting the right platform can make all the difference. Two of the platforms in the industry are Jiga and Xometry. While they offer some similar capabilities, there are some significant differences that can impact your business.

If you are looking for a Xometry alternative, we’ve prepared a full comparison. So let’s get started.

Jiga vs. Xometry: What’s the difference?

The biggest difference between Jiga and Xometry is in their operating model.

While you can only communicate with Xometry’s employees, with Jiga you can communicate directly with the suppliers.

This removes the communication barriers between parties and the “black box” situation, where customers can’t talk to the person who makes their parts.

It makes Jiga a more attractive option when it comes to sourcing complex assemblies and high-volume manufacturing, since it enables higher trust and understanding between parties as well as optimal costs.

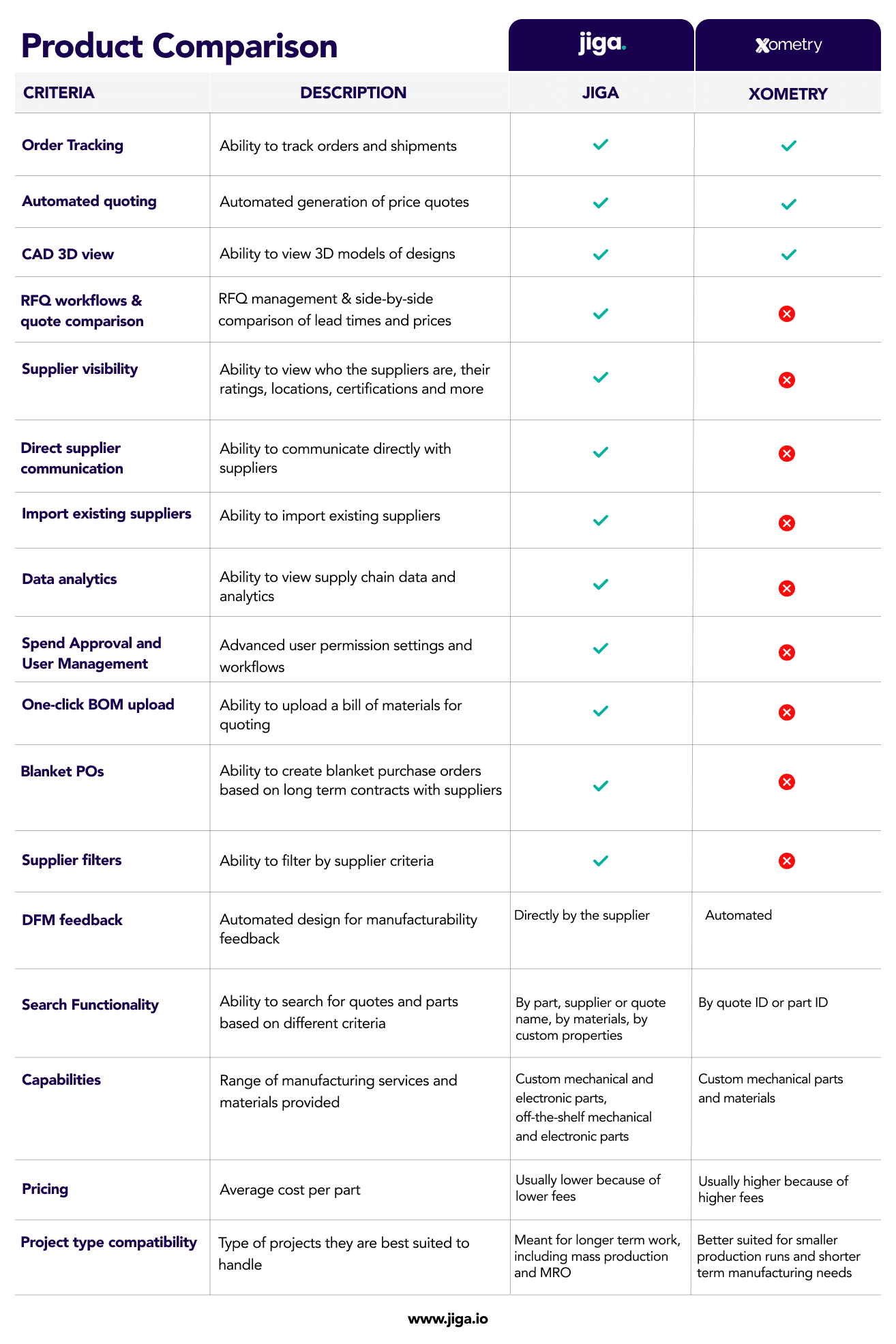

Jiga vs. Xometry: Criteria for Comparison

Supplier Visibility

One of Jiga’s key advantages is their supplier visibility. Businesses can see who the suppliers are, view supplier ratings, locations, certifications, and other crucial information, allowing them to make informed decisions about their manufacturing partners and build a solid supply chain. Xometry does not offer supplier visibility features.

Jerry S.

Mechanical Engineer

"The holy grail of good speed, quality, and price for custom parts"

Jiga is the best way to get the parts you need, when you need them.

Direct Supplier Communication

Jiga allows buyers to communicate directly with suppliers, which can be invaluable in resolving any issues that may arise during production. With Xometry, there are no direct communication channels with suppliers.

Pricing

When we compared a CNC part with a 40.00 x 40.00 x 100.00 mm bounding box, we found up to 37% in cost reduction when using Jiga compared to Xometry, for the part we checked:

Material | Jiga | Xometry | Savings (%) |

Aluminum 7075 | $186.93 | $297.24 | 37% |

Stainless Steel 316 | $141.18 | $213.55 | 33% |

Stainless Steel 304 | $137.67 | $198.83 | 30% |

Jiga’s business model, which allows direct supplier communication, lowers the costs of service and results in lower costs. This is an essential consideration for businesses with long-term manufacturing needs.

Project Type Compatibility

Jiga is an excellent choice for long-term work, such as complex R&D requirements, mass production and MRO, thanks to their competitive prices on high volumes, supplier transparency and collaboration tools. Xometry, on the other hand, is better suited for one-off prototyping, small production runs and shorter-term manufacturing needs.

Capabilities

Both Jiga and Xometry provide a wide range of manufacturing services, such as CNC machining, sheet metal fabrication, 3D printing, injection molding, and laser cutting.

However, Jiga has some advantages when it comes to capabilities:

- Jiga allows you to order off-the-shelf mechanical and electronic parts as well (buy parts).

- In Xometry you can find most of the common materials, which will be enough for most use cases. However, Jiga supports a wider range of niche materials, so if you have a specific need you will probably find what you’re looking for at Jiga.

- Because Jiga allows direct communication between suppliers and engineers, it’s possible to ask for more complex capabilities upon request.

Benjamin S

Mechanical Engineer

"I wish this existed years ago!"

Jiga is the best way to get the parts you need, when you need them.

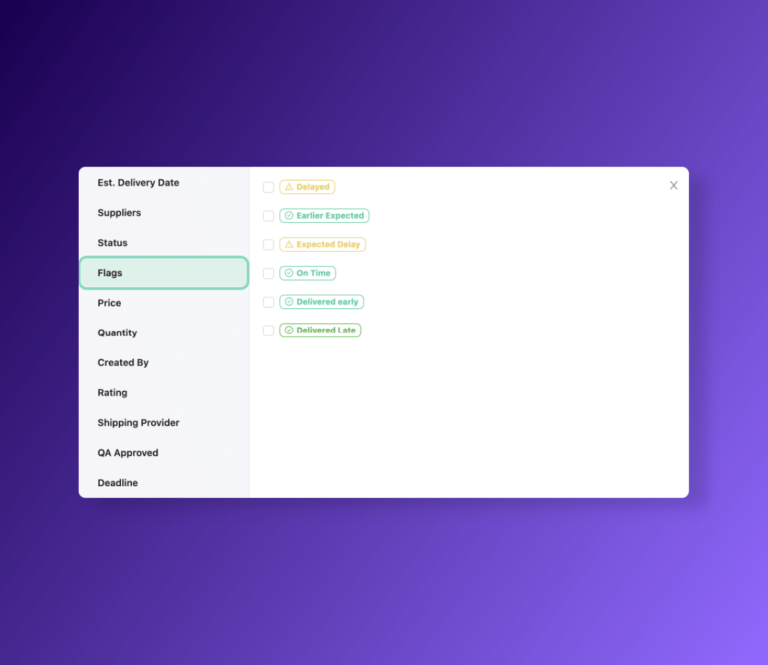

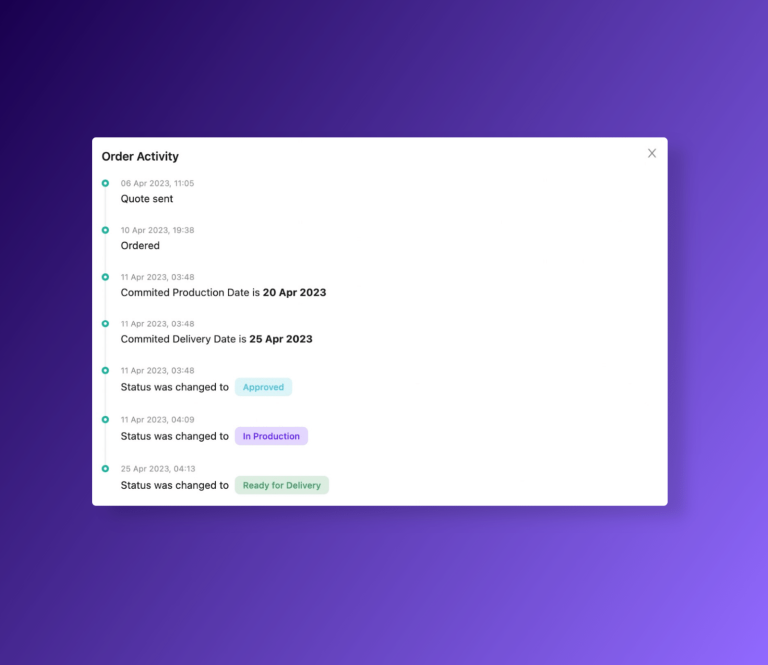

Order Tracking

Both Jiga and Xometry offer order tracking and shipment updates, ensuring that businesses can stay on top of their production schedules.

However, Jiga goes a step further with its order tracking table, which includes advanced features like custom filters, flags for delayed orders, and the ability to compare committed delivery dates versus actual delivery dates.

For example, many customers are choosing to filter based on their own internal PO number, spend category or project name.

Automated Quoting

Jiga and Xometry both offer automated quoting, but Xometry’s automated quoting capabilities are much more robust. Automated quoting makes it easy for businesses to get accurate quotes quickly and tailoring your designs. This feature saves time and helps businesses plan their budgets more effectively. If you’re primarily looking to get quotes instantly, Xometry is the better option.

CAD 3D View

The ability to view 3D models of designs is available on both platforms. This feature is crucial for businesses to ensure that their designs are manufacturable and to make any necessary modifications before production begins.

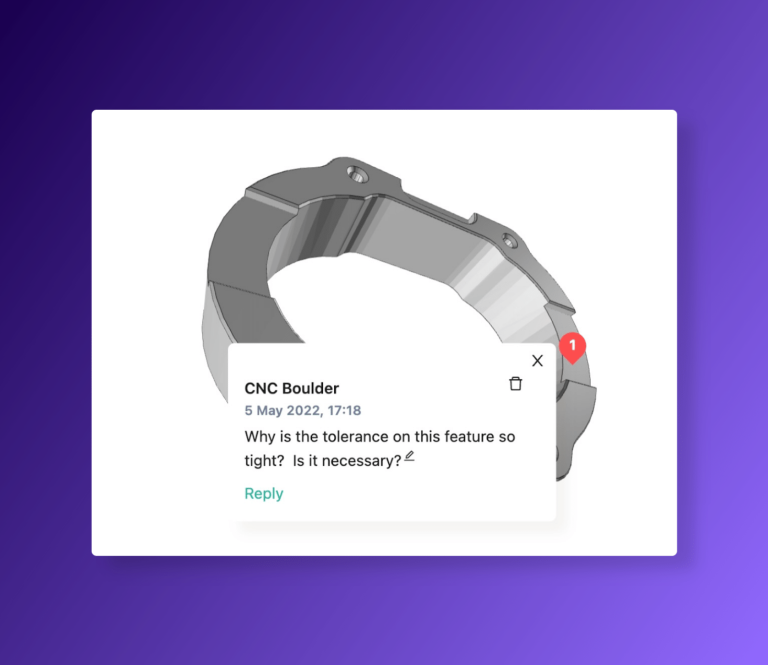

DFM Feedback

Xometry provides automated design for manufacturability (DFM) feedback. This feature enables businesses to identify and address any design issues that could affect the final product’s quality or production time.

Jiga’s approach is different – they rely on the manufacturers for specific and DFM feedback manually using the DfM commenting features. By allowing direct communication between supplier and engineer, the supplier is able to highlight specific concerns or suggestions.

Data Analytics

Jiga’s data analytics feature enables businesses to view their supply chain data and analytics, which can be useful in making informed decisions about their manufacturing processes. Xometry does not offer this level of data analytics.

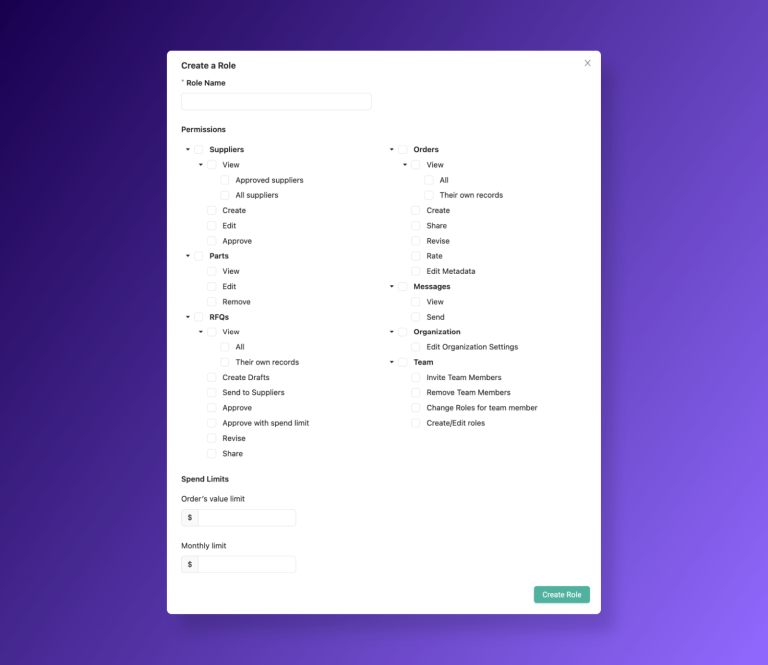

Spend Approval and Users Management

Jiga offers customizable approvals, permissions, and workflows, allowing for a faster purchasing process that fits existing workflows perfectly. Users can customize roles, permissions, and workflows to manage spend approvals and multiple users efficiently. In contrast, Xometry does not provide any spend approval or user management features.

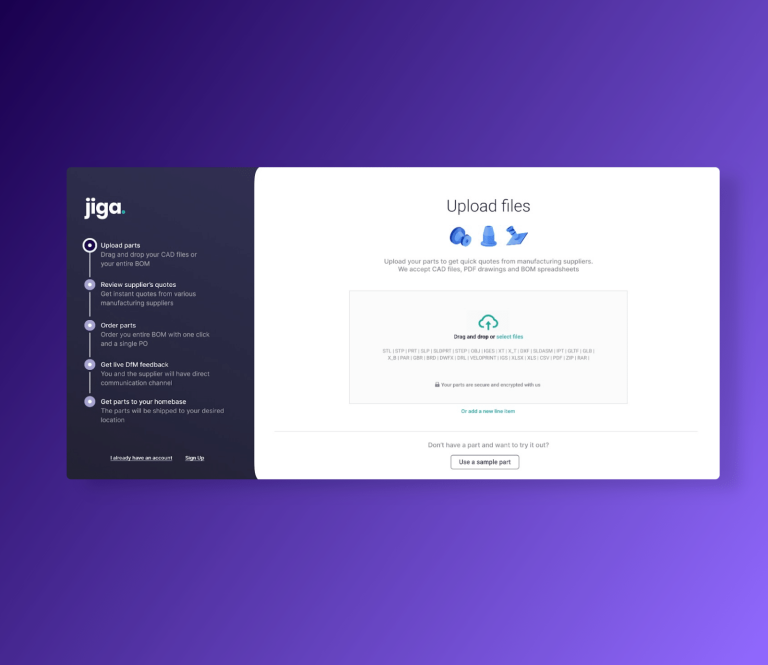

One-Click BOM Upload

Jiga’s one-click bill of materials (BOM) upload feature makes it easy for businesses to upload their BOM for quoting. This feature saves time and eliminates the risk of errors that can occur when manually entering BOM data.

Blanket POs

Jiga allows users to create blanket purchase orders based on long-term contracts with suppliers. This can help businesses save money by negotiating better prices and reducing the administrative burden of placing multiple orders over time.

RFQ workflows & side-by-side quote comparison

Xometry provides a single quote and lead time for each RFQ, while Jiga offers RFQ creation and management with a drag-and-drop interface to add requirements and send the RFQ to multiple suppliers. Once suppliers respond, Jiga provides a side-by-side comparison of lead times and prices, giving businesses more flexibility and transparency when selecting a manufacturing partner.

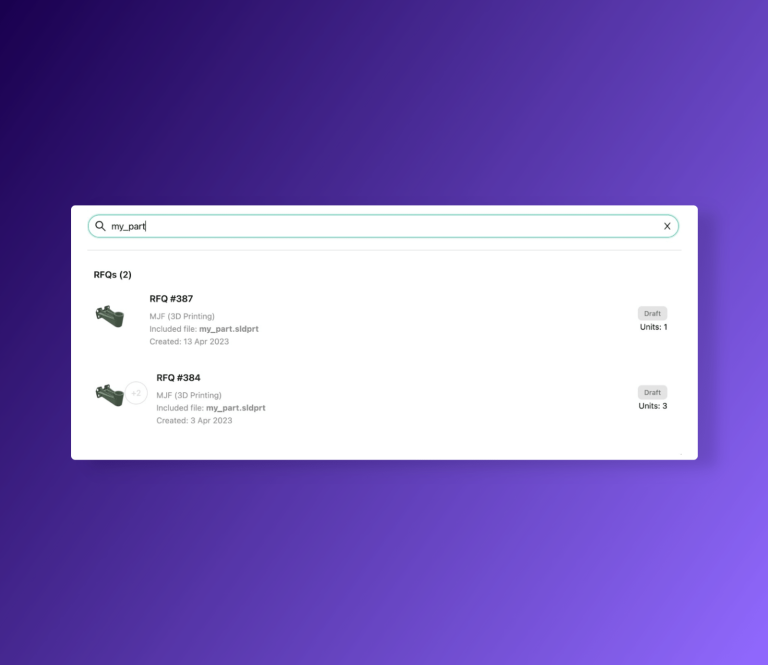

Search Functionality

Xometry allows users to search for quotes and parts by quote ID or part ID. While this can be useful for quickly finding specific items, it may not be as helpful for users who need to search for quotes based on other criteria, such as lead time, material, or supplier name.

On the other hand, Jiga’s platform offers a more robust search functionality. Users can search for files by name, quotes by name, and also by process, material, supplier name, or custom order properties like spend category. This allows users to easily find the information they need and filter results based on specific criteria.

Conclusion: Is Jiga a good Xometry alternative?

In conclusion, choosing between Jiga and Xometry depends on your business’s specific needs and priorities. Both platforms offer a range of capabilities and features.

Jiga is a good choice for more complex, long term manufacturing needs because of its supplier visibility, direct communication, data analytics, and collaborative platform. Xometry operates a large global manufacturing network with a large amount of capabilities and materials, and works great for quick, simple R&D needs.

Ultimately, the goal is to find a reliable and efficient platform that can handle your manufacturing needs and help you achieve your business goals.