Welcome to the first interview of our new series Jiga’s Manufacturing Experts – interviews with experts and influencers in manufacturing, from additive manufacturing, CNC machining and supply chain automation. Jiga’s Manufacturing Experts will show you how hardworking people are building the future of manufacturing and the innovative ways things are made!

Today we host Eliana Fu – Industry Manager for Aerospace & Medical at TRUMPF North America.

She is a thought leader in the Additive Manufacturing industry and an expert in Aerospace and Traditional Manufacturing, Materials Science, and Engineering. She’s also an Ambassador for Women in 3D Printing.

Fun fact: Eliana is the first female engineer at Relativity Space. Where she explored and developed AM applications in building rocket structures and parts.

What's your background?

I have an engineering background with a Masters and PhD in materials science from Imperial College, London. I’ve worked my entire career in engineering with the focus on aerospace and space and my particular interest these days is Additive Manufacturing. My other passion is for titanium, I just think it’s the best engineering material around!

Tell us about your role at TRUMPF North America

At TRUMPF in North America I am Industry Manager for Aerospace and Medical, so that means, if people want to talk to me about how to use laser technology including laser AM in either of those industry sectors, I’d be happy to help.

Did you choose Additive Manufacturing or did it choose you? Why or How?

I come from a traditional metals manufacturing background. In Sheffield, UK, I worked at a traditional forge shop and later, in a titanium processing plant. I realized more and more of my customers were asking for products for 3D printing almost at the same time that fewer and fewer jobs were available for say “titanium forge product metallurgist” and more and more jobs were available for “Additive Manufacturing engineer”. That’s when I realized I needed to learn more about the processes and materials and I really got deep into the subject when I joined SpaceX and then later, in more depth with Relativity Space.

Alan B.

Mechanical Engineer

"Hands-Down the Best Platform and Partner for Fast, Quality Parts"

Jiga is the best way to get the parts you need, when you need them.

What are the AM applications that you find most interesting?

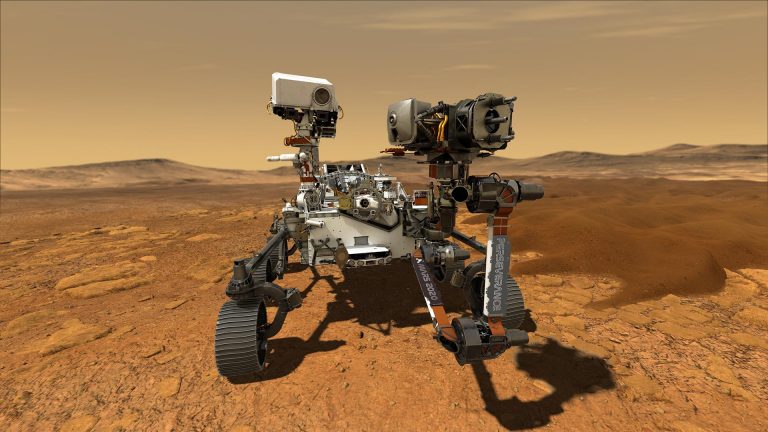

There are so many uses of Additive Manufacturing these days from consumer products to biomedical and automotive. But I gotta say that the most interesting use case for me are anything to do with Space Exploration, from either launch vehicles, to rocket engines, to brackets and supports, turbomachinery and fuel tanks. People are printing now on the ISS (International Space Station) and the future projects of printing in the vaccum of space and on other planetary bodies, is absolutely mind-blowing!

What are the most challenging problems in AM today?

There’s a common mis-conception that you can simply print whatever you want – this is not true. We are limited now by the different kinds of material that can be printed, feedstock availability and process (equipment build volume). The whole process of AM also needs to be more sustainable and economic. We haven’t solved all of those problems yet, but we are getting there.

What excites you most about AM?

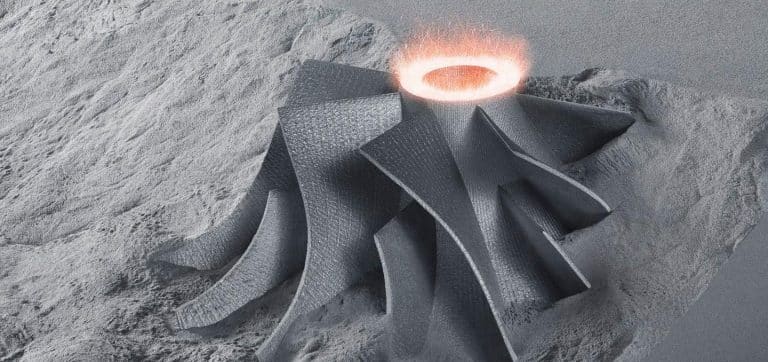

Since I came from a place where the principles of traditional metal working essentially hasn’t changed much since the Bronze Age (or at least the Iron Age), I am continually astounded that reducing the heat source to rapidly melt and solidify metal, can be accomplished with focused laser light the size of a pin-head and then make parts that become a rocket engine. If you don’t understand how mind-blowing this is, then I really don’t know if I can help you — please reach out and get involved!!

Which AM applications do you believe to be the most impactful in the foreseeable future?

In the future we will see 3D printing and AM become more commonplace, the average person in the street will understand what 3D printing is, and we’ll see more customization and printing to order, whether it’s a pair of shoes or a customized 3D printed rib-cage. I think the understanding of AM and where it can be used, will be more impactful as we can reduce leadtimes and difficulties in the Supply Chain by printing “on-demand”. Stay tuned for more exciting advances in the world of AM!

Benjamin S