Xometry stands out for its broad service range, promising to simplify your procurement process for custom parts and prototypes. But, it’s wise to compare.

While Xometry simplifies sourcing custom parts with a vast network and automated quoting, its “black box” approach might limit direct supplier engagement.

For engineers eyeing Xometry, it’s key to evaluate how its services mesh with specific project needs.

Balancing Xometry’s strengths against its limitations is crucial for finding the right digital manufacturing solution

Here’s a closer look at Xometry’s platform:

Pros

✅ Xometry’s vast network of manufacturing partners and automated quoting system enable competitive pricing.

✅ Xometry has an automated quoting algorithm offering instant quotes and DFM feedback for a wide range of processes and materials.

✅ A key strength lies in their network of manufacturing partners, encompassing a wide range of capabilities.

Cons

❌ It prevents direct interaction with suppliers, employing a ‘black box’ model. By preventing direct interaction with suppliers, it does not only obscure the manufacturing process but also hamper customization, quality, and the critical aspect of relationship building with partners.

❌ Interactions are mediated by a middle man, leading to potential miscommunications, inefficiencies, and increased supply chain risk.

❌ Shops often express concerns about the platform’s impact on their operations and profitability, racing them to the bottom, using Xometry as a way to fill available capacity. This feedback matters because it can influence the quality of service and product you receive as a client.

Many are on the lookout for Xometry alternatives that might better suit their needs. Continue on to explore some of the best alternatives available in the market. This comparison does not claim to be definitive – it is based on customer feedback about these companies and on our observations.

9 Best Xometry Alternatives and Competitors in 2024

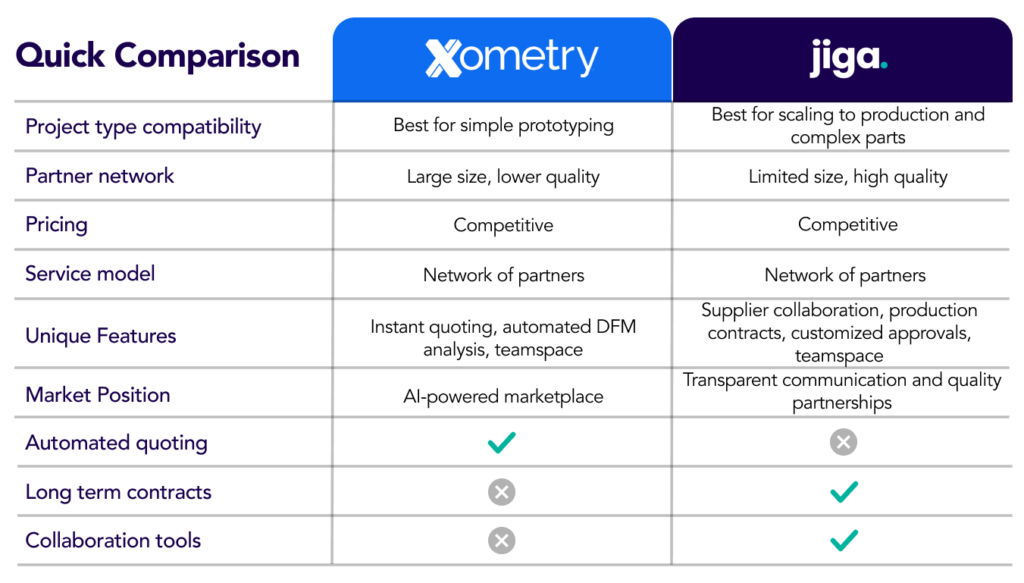

1. Jiga

Communicate directly with Jiga’s manufacturing partners for DFM feedback and collaborate with your team

Jiga is a custom manufacturing service provider that connects a trusted supplier base to a well treated customer base to seamlessly manage complex communications and supply chain processes for great outcomes.

Jiga offers manufacturing services through its exclusively-vetted supplier network, providing the tools for users to select and communicate directly with their partners, while guaranteeing high-quality delivery.

This approach is widely viewed as a deal for more complex sourcing and production work that depends on in-depth communication and building strong buyer/supplier relationships.

Pros

✅ Jiga’s platform presents direct interaction with with manufacturing partners, delivering higher-trust relationships and higher quality by fostering transparency and mutual understanding, making it a great solution for long term production.

✅ Jiga has a very robust and collaborative platform that enables effective internal and external collaboration with powerful data tracking features.

✅ Jiga’s partner network is smaller and more vetted, known as leading to greater engagement and higher quality from partners.

Cons

❌ Jiga doesn’t aim to be the fastest service, so their lead-times can sometimes be less competitive than other services.

❌ Jiga doesn’t provide an instant quoting engine which can be viewed as a weakness for quick turn, rapid prototype parts.

❌ Jiga’s network of partner suppliers is smaller, therefore seen as more limited.

Read more about Jiga vs. Xometry.

Jerry S.

Mechanical Engineer

"The holy grail of good speed, quality, and price for custom parts"

Jiga is the best way to get the parts you need, when you need them.

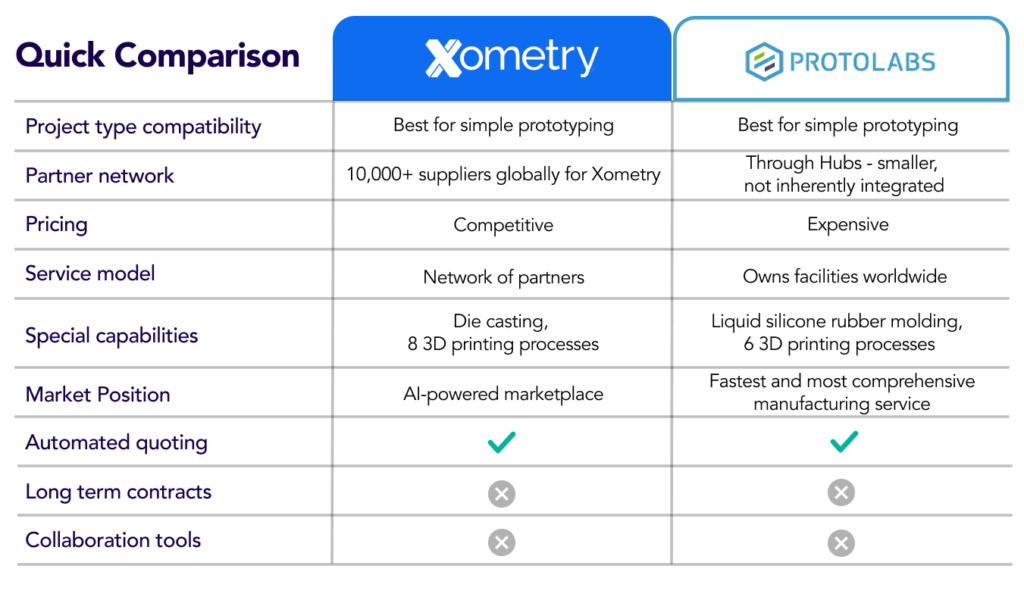

2. Protolabs

Protolabs was founded in 1999 in Maple Plain, Minnesota, USA, by Larry Lukis. Originally named ProtoMold, the company started as a provider of rapid injection molding services.

Over the years, Protolabs expanded its capabilities and evolved into a leading digital manufacturing company, offering a wide range of services, including CNC machining, 3D printing, injection molding, and sheet metal fabrication. The company went public in 2012 and has since grown into a global leader in on-demand manufacturing.

Pros

✅ Fast lead times in rapid prototyping and on-demand manufacturing at small volumes.

✅ Diverse manufacturing capabilities from a wide range of manufacturing technologies.

✅ Their user-friendly online platform provides customers with instant quotes, design analysis tools, and order tracking capabilities.

✅ Owning their equipment, they ensure streamlined operations with fewer complications, delivering a simpler purchasing process.

Cons

❌ They are less suitable for scaling to production (ideal for quick turn prototyping runs).

❌ Online submissions are general toleranced, which leaves the client having to do post-work for items like preparation for press fitting, requiring clients to ream holes after delivery.

❌ They are limited to their machines so they can say yes to less types of jobs.

❌ Their pricing is often viewed as more expensive.

❌ Some specialized or exotic materials may not be available through their service.

❌ They’re widely viewed as less suited to more complex parts/assemblies and higher tolerance parts.

Despite this, they are a recognized leader in the digital manufacturing market, with a strong brand reputation and significant market share. The company’s emphasis on speed, quality, and innovation has positioned it as a preferred partner in rapid prototyping.

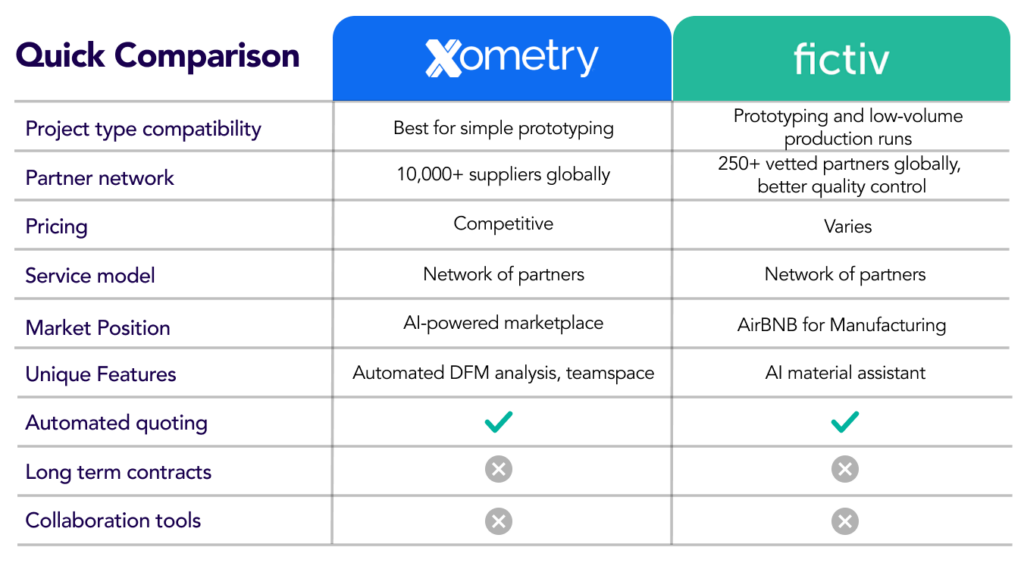

3. Fictiv

Fictiv was founded in 2013 by Dave and Nate Evans in San Francisco, California. The company was established with the mission of democratizing access to manufacturing by providing a digital platform that connects customers with a network of manufacturing partners. Fictiv has since expanded its operations and offerings, becoming a leading provider of rapid prototyping and on-demand manufacturing services.

Pros

✅ Agile manufacturing support through providing rapid prototyping and on-demand manufacturing solutions, offering short lead times.

✅ Their user-friendly online platform provides customers with instant quotes, design analysis tools and order tracking capabilities.

✅ They offer stringent quality control processes and work closely with manufacturing partners to ensure conformance.

✅ Fictiv has a global network of manufacturing partners, allowing it to offer localized production and support services to customers worldwide.

✅ They provide better customer support and technical assistance to address any questions or concerns.

Cons

❌ In 2024, Fictiv ventured into sheet metal and die casting, technologies where Xometry is more seasoned, indicating Fictiv’s relative inexperience.

❌ Not exposing the manufacturer, customers seeking transparency and ownership over their supply chain are hesitant to progress beyond R&D.

❌ They offer a wide range of materials for manufacturing, but some more special options may not be easily available.

❌ Their rapid prototyping and on-demand manufacturing services will generally be more expensive than traditional manufacturing sources for larger production volumes, trading price for speed.

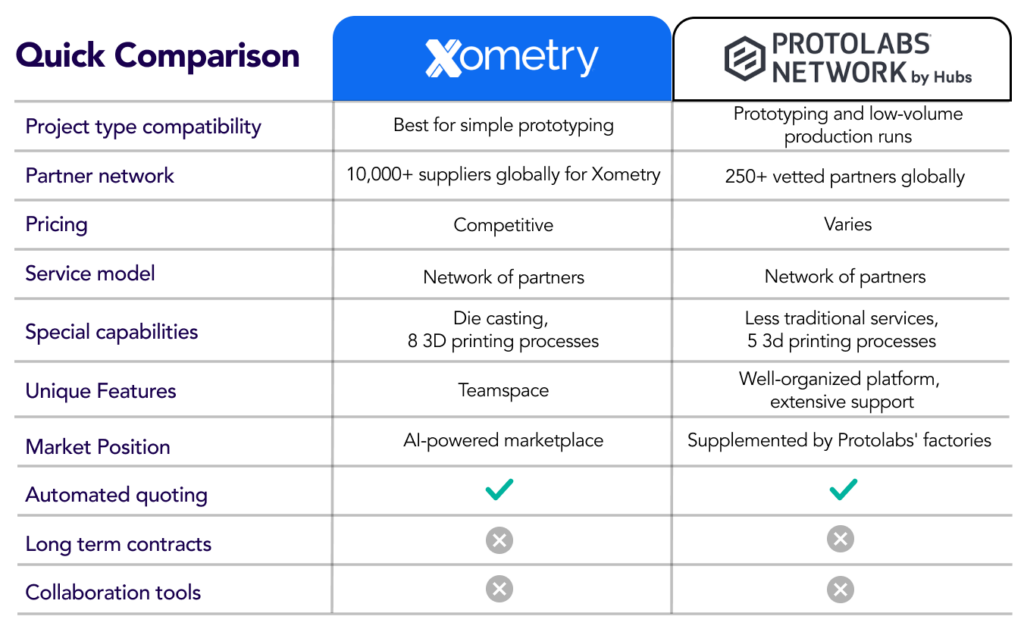

4. Hubs

Hubs (formerly 3D Hubs) was founded in 2013 by Bram de Zwart, Brian Garret and Filemon Schöffer in Amsterdam. Initially, 3D Hubs operated as a peer-to-peer network, allowing individuals and businesses to connect with local 3D printing service providers for on-demand manufacturing. Over time, 3D Hubs evolved into a full service digital manufacturing platform, offering CNC machining, injection molding and sheet metal fabrication.

Hubs offers a variety of digital manufacturing services from a network of manufacturing partners. Hubs is known for its strength in Europe, providing digital manufacturing with a partner network. It faces competition from Xometry, which has a broader presence in the US. The integration with Protolabs might lead to operational challenges for Hubs, affecting its network efficiency.

Pros

✅ They have built a global network of manufacturing partners, so they can localize supply to the customer in many cases.

✅ They provide access to a broad spectrum of digital manufacturing technologies and processes, to meet customers requirements.

✅ Hubs’ online platform offers a seamless and user-friendly experience for uploading designs, obtaining instant quotes on simpler parts and managing supplier communications.

Cons

❌ High-volume manufacturing capabilities may be limited, affecting suitability for larger scale projects.

❌ Offers a broad selection of materials; however, access to some exotic materials may be restricted.

❌ Generally, costs are higher for large-volume orders compared to traditional manufacturing, prioritizing speed and flexibility.

❌ The “black-box” approach limits transparency, making some customers cautious about deeper supply chain engagement.

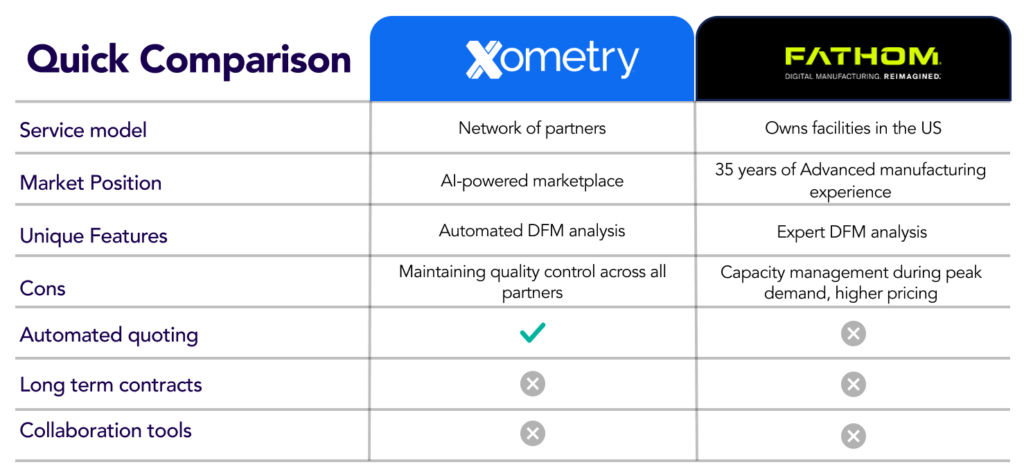

5. Fathom

Fathom was founded in 2008 by Rich Stump, Michelle Mihevc, and Danny Richter in Oakland, California. They began as FATHOM Rapid Prototyping & 3D Printing, offering rapid prototyping and additive manufacturing services. Over the years, the company expanded its capabilities and evolved into a comprehensive digital manufacturing solutions provider, serving clients across various industries.

Fathom provides the well understood range of digital manufacturing services, with some standout areas being;

- Utilizing technologies such as FDM, SLA, SLS, and PolyJet for rapid prototyping and production-grade parts.

- Low to medium-volume production of plastic parts using injection molding techniques.

- Prototyping and low-volume production using silicone molds and urethane resins.

- Assisting clients with product design, optimization and validation.

- Providing surface finishing, painting, and assembly services to meet client specifications.

Pros

✅ Offering a wide range of digital manufacturing solutions under one roof and direct control, including additive manufacturing, CNC machining and injection molding.

✅ Fathom’s team comprises experienced engineers, designers, and manufacturing specialists who provide high-grade expertise and support throughout the product development lifecycle.

✅ Maintaining stringent quality control measures and certifications to ensure the accuracy and reliability of manufactured parts.

✅ Fathom emphasizes collaboration with clients, offering design feedback, material selection guidance, and project management support.

Cons

❌ Challenges in managing production capacity during peak demand periods or for large-scale projects, causing late delivery at times.

❌ Higher pricing compared to some competitors, particularly for specialized services or premium materials.

❌ Standing out from other digital manufacturing service providers with similar capabilities and offerings.

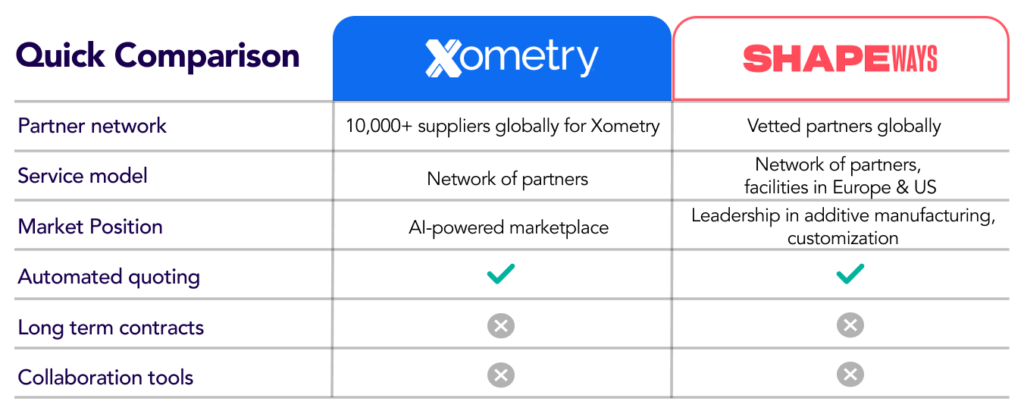

6. Shapeways

Shapeways was founded in 2007 by Peter Weijmarshausen, Marleen Vogelaar, and Robert Schouwenburg in Eindhoven. The company started as a 3D printing marketplace, allowing users to upload their designs and have them printed using various technologies. Shapeways has expanded its offerings and evolved into a leading provider of additive manufacturing services.

They also offer the typical range of digital manufacturing services, with the less common offerings being;

- Design services for optimization and customization are offered to help customers create and refine their designs.

- A wider materials variety, including plastics, metals, ceramics and composites, allowing customers to be more selective for their application needs.

- Finishing and post-processing services, such as sanding, polishing and painting, to enhance parts.

Pros

✅ Shapeways offers a diverse selection of materials and 3D printing technologies, enabling customers to produce parts with a variety of properties and select high quality finishes.

✅ They provide design optimization and customization services to help customers create unique and innovative products tailored to their specific requirements, though this is process and aesthetics focussed more than engineering targeted.

✅ They present a global manufacturing network, allowing them to offer local based manufacture and support services to customers worldwide.

✅ Community and Marketplace: Shapeways fosters a vibrant community of designers, artists, and makers, providing a platform for collaboration, inspiration, and creativity.

Cons

❌ Lead times for production and delivery vary depending on factors such as material availability, manufacturing capacity, locale and shipping logistics.

❌ While Shapeways offers competitive pricing for low to medium-volume production runs, larger quantities or specialized materials tend to be uncompetitive.

❌ They are limited to 3D printing and do not have a significant presence in other technologies.

They’re a leader in additive manufacturing, with a significant market share and a reputation for innovation and quality. An emphasis on customization, design flexibility and community engagement has positioned them as a preferred platform for designers and creators seeking on-demand manufacturing solutions.

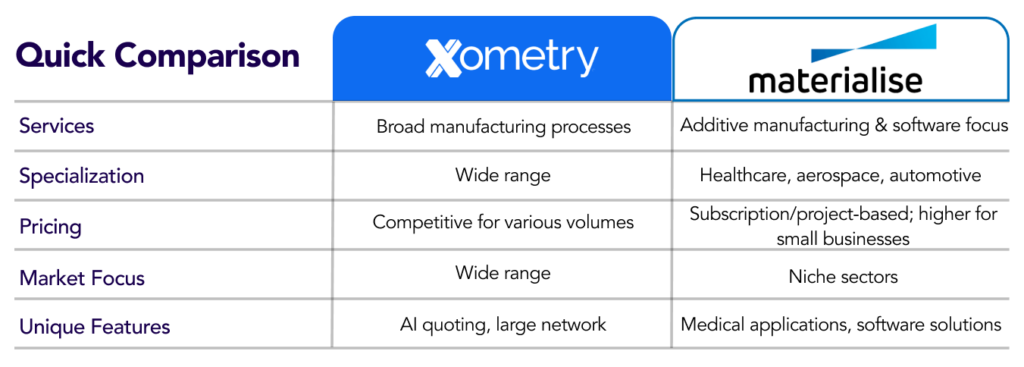

7. Materialise

Materialise was founded in 1990 by Wilfried Vancraen in Belgium. It began as a service bureau for 3D printing and software solutions for additive manufacturing. Over the years, Materialise has grown into one of the leading providers of additive manufacturing software and services globally.

Materialise offers a comprehensive suite of products and services, the more unusual ones being;

- Software solutions for various stages of the additive manufacturing process, including design optimization, 3D printing preparation, simulation and quality control.

- Materialise specializes in medical 3D printing applications, including surgical planning, custom implants and anatomical models for preoperative planning and education.

- Aerospace and automotive solutions, additive manufacturing solutions for aerospace and automotive industries, including lightweighting, topology optimization and supply chain optimization.

Materialise employs various pricing models depending on the product or service being offered. For software solutions, Materialise typically utilizes subscription-based pricing. For 3D printing services and medical solutions, Materialise may use a project-based pricing model, where pricing is determined based on part complexity, material usage and other project requirements.

Pros

✅ Materialise offers a range of advanced software solutions for additive manufacturing, providing customers with powerful tools.

✅ They have extensive experience in medical 3D printing applications, making Materialise a trusted partner for healthcare professionals and medical device companies.

✅ The company has a global presence with offices and production facilities in Europe, North America and Asia, allowing it to offer regionalized support and services to customers in key market geographies.

✅ Materialise collaborates with leading companies and research institutions in various industries, fostering innovation and advancing the integration of additive manufacturing technologies.

Cons

❌ Materialise’s software solutions and services are generally too costly for small businesses or startups, limiting their integration at early-stage.

❌ Their business is closely tied to the growth and adoption of 3D printing technologies, rendering them vulnerable to paradigm shifts in a fast market.

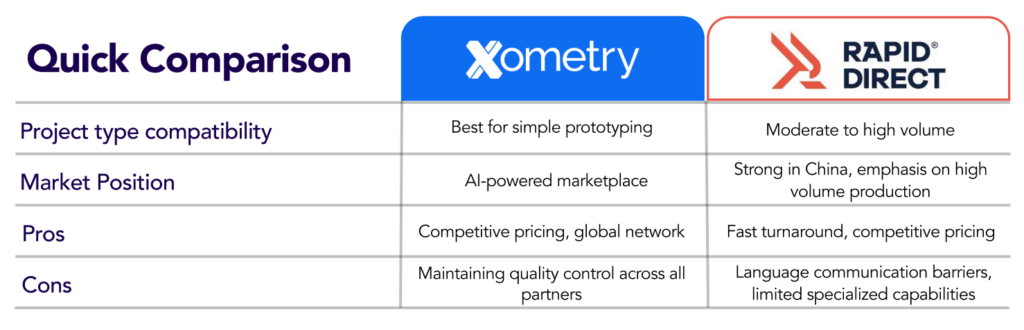

8. Rapiddirect

RapidDirect was founded in 2009, an early entrant to the locally-owned factory sector in Shenzhen. In 2019 they introduced the RapidDirect online manufacturing platform and added their fast quoting feature and automated CNC design for manufacture (DfM) assessment tools. This expanded to introduce 3D printing instant quoting in 2023.

Rapiddirect offers a fairly market-typical range of manufacturing services, with recognized specialization in;

- Low to medium-volume production of plastic parts supply by injection molding with both rapid and industry-norm tooling.

- Offering services like painting, anodizing, sandblasting, chrome plating and more they can enhance the appearance and functionality of parts.

- Assembly and secondary operations such as tapping, threading and heat treatment.

- They offer greater emphasis on moderate to high volume production and maintain good regional connectivity in this.

Pros

✅ Fast turnaround times, both for prototypes and production runs.

✅ High-quality results achieved through diverse manufacturing processes.

✅ Competitive pricing compared to similar service providers.

✅ Extensive experience and expertise in various manufacturing techniques.

Cons

❌ Language and communication barriers for international clients.

❌ Potential challenges in maintaining quality control for complex projects.

❌ Limited capacity or capabilities for certain specialized processes or materials.

Rapiddirect’s market share and positioning depend heavily on its reputation/profile, resulting from the quality of services, pricing, marketing and sales effort and its ability to differentiate from competitors. As a Chinese-based manufacturer, it has a strong presence in both domestic and international markets, leveraging China’s manufacturing capabilities and cost advantages.

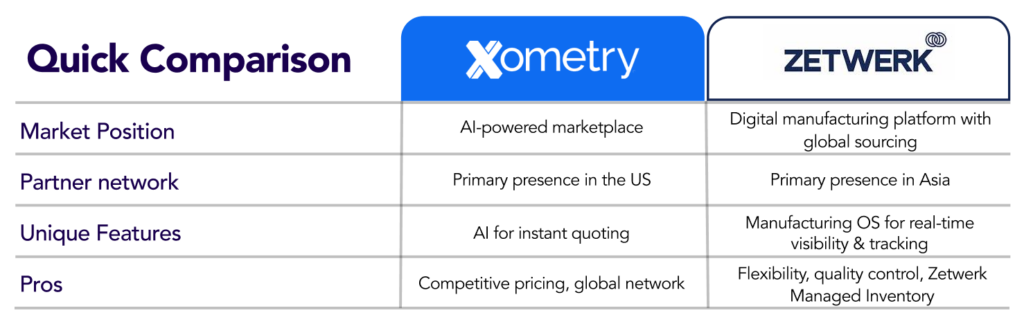

9. Zetwerk

Zetwerk is an indirect manufacturing platform that connects clients and manufacturing suppliers. Founded in 2018 by Amrit Acharya, Srinath Ramakkrushnan, and Rahul Sharma in Bengaluru, India, they seek to streamline the procurement process for manufacturing by efficiently connecting manufacturers to buyers.

Zetwerk offers a market typical range of services and competences and they’re reported as being exceptional in;

- General fabrication services including cutting, bending, welding, and assembly.

- Manufacturing of metal parts through the forging process, both hot and cold.

- Various casting processes; sand; investment; and die casting.

Pros

✅ They have a large network of vetted manufacturing suppliers, offering a very wide range of core capabilities and capacities.

✅ Leveraging digital tools and algorithms, Zetwerk seeks to streamline the procurement process.

✅ Ensuring product quality through supplier evaluation, quality control processes, and certifications.

✅ Zetwerk’s platform allows for flexibility in manufacturing requirements and scalability to meet changing customer demands, as they cover the full spectrum of service volumes.

Cons

❌ Zetwerk’s performance and service quality are only as good as the capabilities and reliability of their network of suppliers.

❌ Challenges in expanding operations and maintaining quality standards in new geographical markets.

Zetwerk aims to position itself as a leading digital manufacturing platform in the global market. Its market share and positioning depend heavily on reputation, the reviewed quality of its services, its pricing competitiveness, its technology infrastructure and its ability to scale operations. By offering a diverse range of manufacturing services, leveraging technology for efficiency, and prioritizing customer satisfaction, Zetwerkis aggressively working to capture market share and become a preferred partner for businesses’ manufacturing needs.

Javier L

Principal Systems R&D Mechanical Engineer

"Game changing in the online manufacturing space"

Jiga is the best way to get the parts you need, when you need them.

Conclusion

Digital manufacturing has emerged as a crucial element in every manufacturing supply chain, offering streamlined services that are vital in navigating the time-consuming, complex and costly process. While Xometry stands out as a prominent service provider, there are certainly other relevant competitors that may offer more suitable alternatives for some.

Not all digital manufacturing services are created equal. Some are ideal for one-offs, some better for volume – and just a few have cracked the alchemy of scalability so they can do it all.

So in conclusion, we wanted to review a comparison that may inform the reader about how to select from a burgeoning field of suppliers with a bewildering array of claims.

The way we see it, working with manufacturing suppliers is about partnerships first. By building those partnerships the right way, you can reap strategic and commercial benefits.

This is also the reason we’ve built Jiga as an alternative to Xometry. It lies in the operating model.

- In simple terms, Xometry provide a black-box service that has the client dealing with Xometry alone and Xometry addressing the bidding and management process.

- Jiga is a right hand assistant and guide. We’re responsible for the parts, assist in every stage, provide management tools to support both parties’ interactions and stand ready to step in to unblock issues at a moment’s notice.

Dealing with your suppliers is a richer, faster and more informative approach than dealing with a middleman. It also results in a more competitive option as a result of reduced operational costs.

It is invaluable in making the flow from concept to mass production a low friction process, free of stage revolutions and hard-end handovers when scaling up. Your product is no longer at risk of being ‘thrown over the wall’ to production, sitting instead in a closely managed continuum of services that just make your job easier.