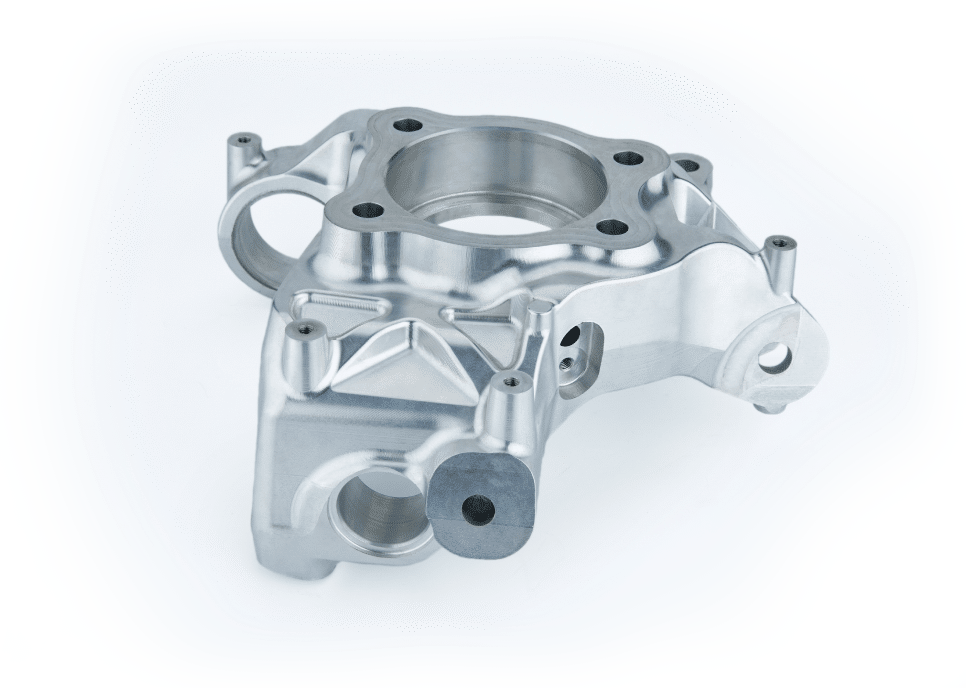

Our CNC Machining Services harness a global manufacturing network to deliver precision components meeting your specifications

Trusted by the world’s top-tier companies

And more…

CNC machining is a modern manufacturing process where computers control machine tools to accurately produce parts from digital designs. This method ensures high precision and consistency, reducing manual effort and improving efficiency. Ideal for a variety of industries, CNC machining enables the production of complex shapes with excellent reliability, making it a staple in precision engineering and mass production.

Jiga’s CNC Machining services delivers precision parts on time through a global manufacturing network. Fast, accurate quotes and direct payment streamline your process, while communication with manufacturers provides crucial DFM feedback. Everything—quotes, orders, communication, and tracking—is centralized for seamless collaboration and efficiency. Jiga guarantees quality, making it the smart choice for your CNC machining needs.

The quality and on-time delivery of your parts is guaranteed by Jiga. Jiga is ISO 9001:2015 and ISO/IEC 90003 certified. Our partners are AS 9100D and ISO 13485:2016 certified with ITAR & EAR options on demand.

Jerry S.

Mechanical Engineer

Alan B.

Mechanical Engineer

Javier L

Principal Systems R&D Mechanical Engineer

Tony K

Senior Mechanical Engineer

Shaked S

Purchasing Manager

George B

CTO

© 2024 Jiga, Inc. All Rights Reserved.