Whether you are planning to produce a single prototype or you are already ready for mass production, the desire to reduce production costs is often a top priority when choosing to use CNC machining.

Fortunately, our decisions as designers have a significant impact on the final price of manufacturing the part or product. By adhering to a number of rules of thumb and simple principles, we will be able to manufacture the product while minimizing costs and maintaining the mechanical requirements of the part.

First let’s briefly review the main factors influencing the price of part production in CNC machining –

Machining time: The longer it takes for the machine to produce the part, the higher its price will be. This is usually the main component when calculating the cost of manufacturing the part.

Initial set-up costs: These costs usually consist of the cost of preparing the machine for the production of the part, such as writing a work plan, resetting the machine, etc. These costs have great significance when it comes to producing parts in small quantities and the main way in which they can be reduced is by increasing the production quantities of the parts to a cost-effective quantity.

Raw material price: The cost of the raw material and the level of complexity required to process it is a component that greatly affects the cost of production of the part itself.

Now that we have broadly understood what factors influence the production of parts CNC machining, let’s see how these costs can be reduced!

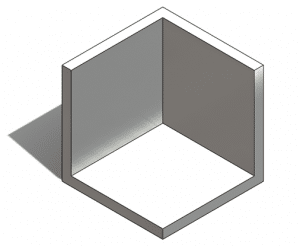

1. Add internal radii rather than sharp corners

A very common design mistake is to leave sharp corners in inner pockets in the 3D model we designed.

Because all the CNC machining milling tools currently on the market are cylindrical in shape, it’s very difficult to produce sharp inner corners with CNC milling.

The radius of the corner can be reduced by using a smaller diameter milling tool.

This will cause the milling tool to have to go around the corner several times at a low speed, which in turn will increase the working time of the machine and the final cost.

This cost can be reduced with a few simple tips:

Try to make sure the corner radius is about ⅓ in size from the depth of the inner pocket (a larger radius is even better)

If possible, make sure that the radius is the same in all corners.

At the bottom of the inner pocket, set a very small radius or if possible leave it with no radius at all.

It’s the most ideal if the radius of the inner corner is slightly larger than the radius of CNC milling that is supposed to create the inner pocket. Such a design reduces the load and will allow milling more quickly which in turn will result in lower production costs.

For example, if our pocket depth is 12mm, we would like to set the radius of the corners to at least 5mm in size. Choosing these sizes will allow us to use 8 mm diameter milling (with a radius of 4 mm) and mill more quickly.

It is advisable to avoid sharp corners in the inner pockets of the planned part.

If sharp corners are still needed in the inner pocket (for example if a square part needs to fit the same pocket) an inner milling can be used (as in the picture below) instead of reducing the radius of the inner corner.

Jerry S.

Mechanical Engineer

"The holy grail of good speed, quality, and price for custom parts"

Jiga is the best way to get the parts you need, when you need them.

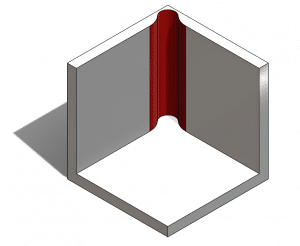

2. Limit the depth of the inner pockets

Deep pocket milling is an operation that can significantly affect the cost of part production, the reason being that deep pocket milling in the part requires removal of a large amount of the raw material, an operation which takes a lot of work time for the machine.

It is important to remember that a CNC milling tool has a limit on the depth at which CNC milling can penetrate the raw material, a rule of thumb that works well is that milling can penetrate (and work optimally without extreme mechanical loads) to a depth equal to its radius (half the diameter).

For example, if we use 8 mm diameter milling, we can mill one pocket at a depth of 4 mm.

Deeper pockets can be milled, but performing such an operation may lead to an increase in the price of the part since in order to perform such CNC milling additional special equipment is needed.

In milling inner pockets there are some rules of thumb that you should pay attention to

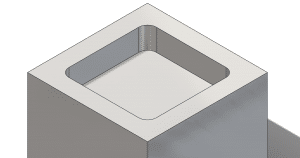

3. Increase wall thickness

In general, if the weight of the part is not a critical factor, hard and thick walls are more stable (and often also cheaper to manufacture) so it is better to design the parts accordingly.

Another reason is that in order to produce thin walls, a number of milling moves have to be made at a shallow depth. In addition thinner walls are susceptible to vibrations, so milling them accurately is a complex and challenging operation which increases the working time of the machine significantly.

The following rules of thumb can be considered when planning wall thickness in the part.

For metal parts, it is recommended to design walls with a minimum thickness of 0.8 mm.

For plastic parts, it is recommended to maintain a minimum thickness of 1.5 mm.

It is worth remembering that most of the time, the minimum thickness that can be obtained in metals is around 0.5 mm and in plastic parts it is 1 mm (lower thicknesses can be reached but each case must be examined on its own).

In many cases such a thickness will be obtained when designing two drills that are too close to each other or when placing a drill near the end of the part, so it is advisable to follow these rules of thumb when designing the parts.

It is advisable to increase the thickness of the walls in order to lower the production time and cost

4. Avoid engraving text on the part (especially in prototypes)

Although engraving text on the part is aesthetically pleasing, it is an operation that requires a lot of processing time of the machine, so if it can be avoided (especially in prototypes) then it is better.

This is because in order to mill symbols, letters, logos, etc. the machine uses finger milling to remove a layer of material in a way that will create these symbols.

This action is indeed very aesthetically beautiful and may even be necessary for the use of the part. But it is advisable as far as possible to postpone it to the mass production stage of the part, thus making it more economical.

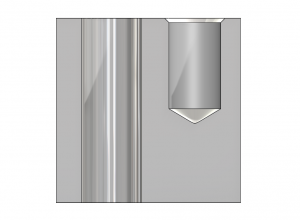

5. Limit the depth of the threads

Designing the part with threads and taps longer than their actual need may increase the cost of manufacturing the entire part, as the need to use special equipment may arise.

For example, when planning a thread in part, a rule of thumb to keep in mind is that the minimum depth of the tap hole should be half the diameter of the screw, a deeper hole will not significantly contribute to the strength of the connection.

Another rule of thumb that should be followed is that as far as possible the part is designed so that the maximum depth of the tap bore will be 3 times the diameter of the screw.

It is advisable to observe a number of rules of thumb when planning taps and drills in the part

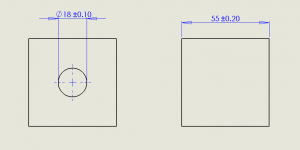

6. Use standard size drills

Creating drills with machining can be a simple and quick operation with great precision when using standard size drills. When you want to create drills in special sizes, it is necessary to use special mills or cutting knives, which in turn can increase the cost of production.

In addition, try to limit the depth of the bore to a size of 4 times its diameter. Deeper boreholes can be produced but there is a good chance that special equipment will need to be used, and the price of the part will go up.

Other things to keep in mind when planning a drill in the section:

-design drills whose diameter varies in jumps of 0.1 mm in sizes up to 10 mm, and in jumps of 0.5 mm in sizes beyond 10 mm.

-Try to keep the depth of the drill not to exceed 4 times its diameter.

7. Set tight tolerances only where it is necessary

Setting tight tolerances can significantly increase the price of the part because this action has 2 main implications.

The first is that as you want to reach a higher level of accuracy it is necessary to use a number of additional tools or moves of the processing machine which in turn increases the production time.

In addition, after production, it is necessary to perform a manual check that the part meets the accuracy requirements. Unless otherwise stated in the part drawing, the standard tolerance is usually 0.1 mm, and it can usually suffice for non-critical uses and features.

So the bottom line is we need to think about where we want to emphasize the level of accuracy required in the part.

Patrick J