Design for Assembly (DFA) is a design principle and methodology in product design and assembly module definition that optimizes the ease and efficiency of assembling a product, to reduce production costs and enhance product quality and reliability. This approach considers how to assemble a product from its individual components right from the initial design stage.

This article will offer some guidelines as to how to approach this as an integral part of the product definition that influences and affects design choices from the concept stage through to mass production and beyond.

What is Design for Assembly (DFA)?

In product design and manufacturing, engineers use DFA to optimize the efficiency of assembling components, integrating it as a central consideration in the design process. The core intention of DFA is to minimize the cost, time and challenges involved in starting and perfecting the assembly process and execution.

Below, we introduce a few key principles and considerations that drive the DFA process, providing enough background to initiate a discussion about good practice.

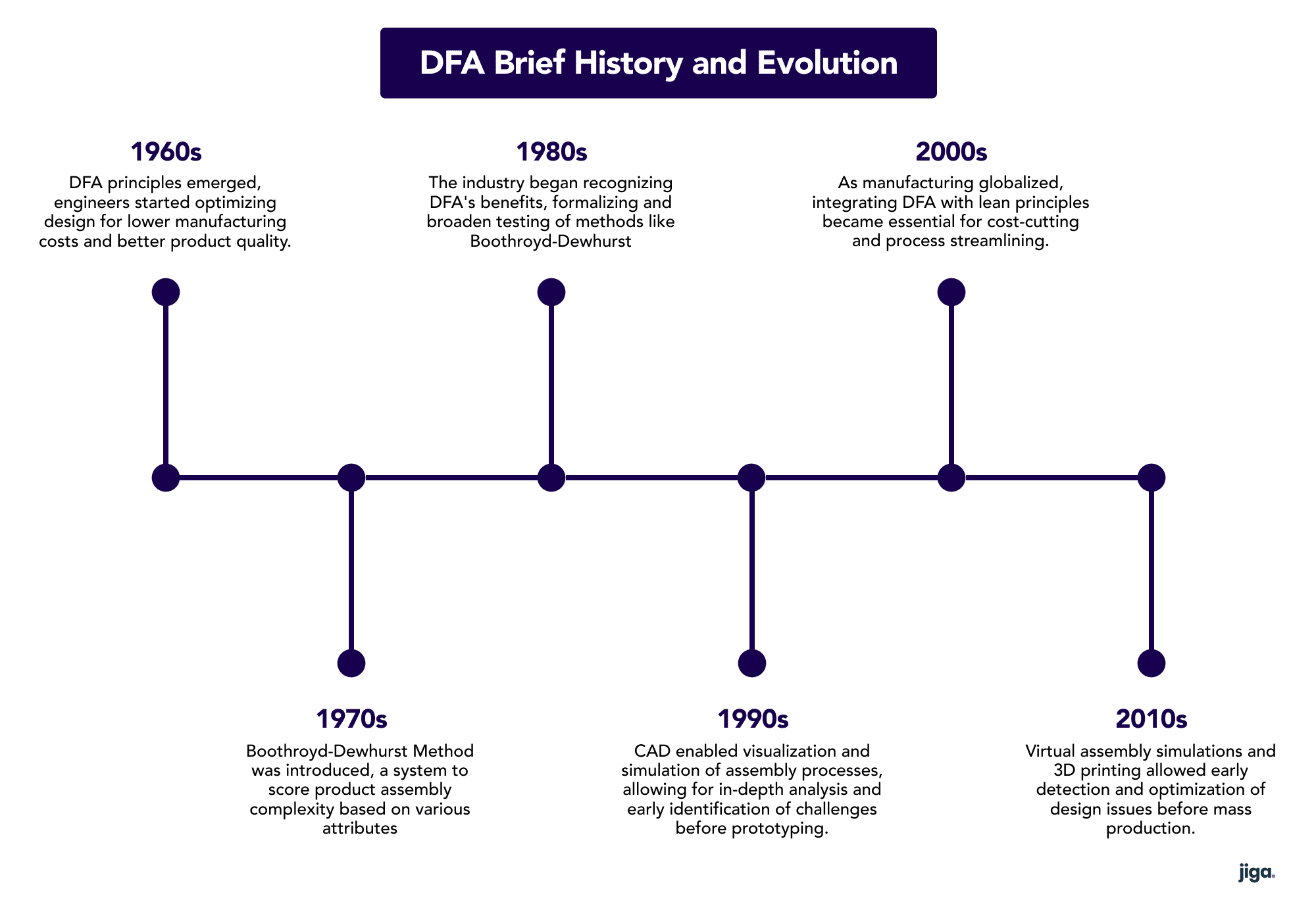

Brief history and evolution of DFA

Design for Assembly (DFA) has its roots in the broader field of design and manufacturing optimization, which has become increasingly formalized throughout the period since the industrial revolution.

- Early history – examples abound of improving design practice to optimize mass production. Henry Ford was one of the earliest to understand this process. He understood that the design and manufacture were a continuum that improved manufacturability and therefore margin.

- 1960s to 1990s – DFA developed from an experienced understanding among engineers/designers, into a formal and taught process.

- 2000s to the present – Lean manufacturing has embraced DFA as a pillar, and it is increasingly being implemented in sophisticated and rapidly evolving CAD environments.

- Current Trends – Integration of Sustainability: DFA is evolving to encompass consideration of sustainability. Designing products with assembly efficiency contributes to reduced material and energy consumption.

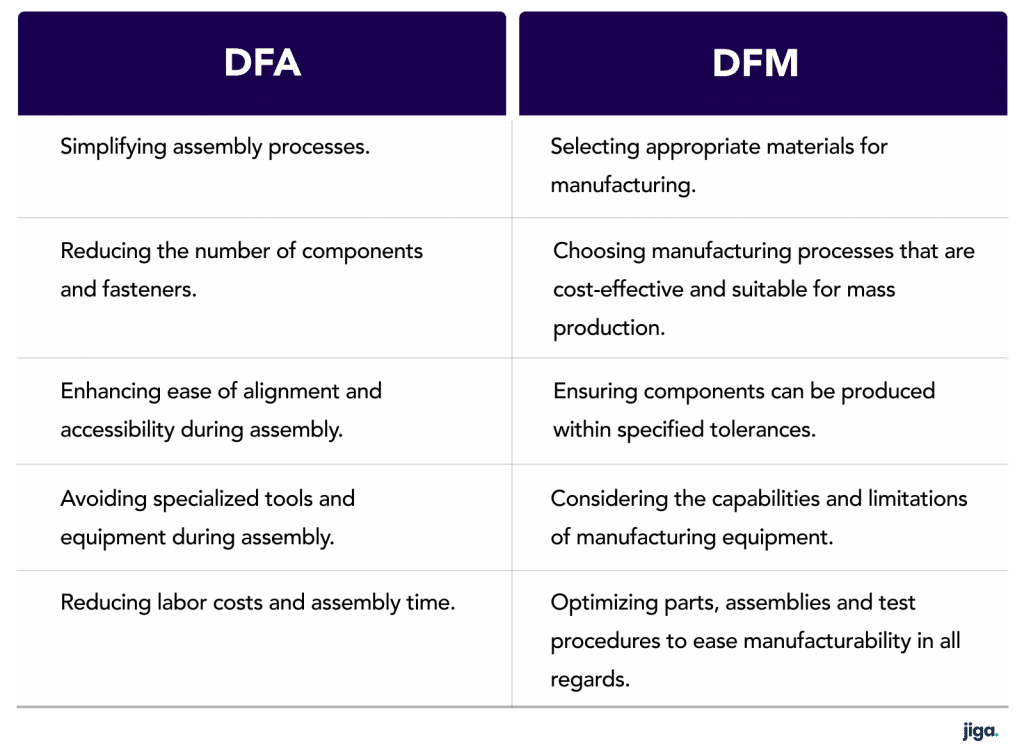

What’s the difference between DFA and DFM?

Design for Assembly is a subset of skills and practices within the broader methodology of Design for Manufacturing (or Design for Manufacturability, or Manufacture).

DFA focuses on designing products in a way that minimizes the complexity of assembly processes. The goal is to make the process quicker and less error prone. It involves analyzing design features that complicate assembly, such as unnecessary part count, irregular or unreliable fasteners, difficulties in access and creating simple solutions.

Jerry S.

Mechanical Engineer

"The holy grail of good speed, quality, and price for custom parts"

Jiga is the best way to get the parts you need, when you need them.

DFA Principles of Application

Here we outline the guiding principles and what call to action results in real terms.

Use of sufficient tolerances

The tolerancing process is at the heart of the DFA (and broader DFM) process:

- Use the lowest tolerances that can deliver the functionality and robustness required.

- Recognize the need to consider tolerance stack-up and its impact on assembly and/or function.

- When the overall ‘height’ of a multipart assembly is restricted, consider using tolerance allocation as a tool to control the assembly height.

In some regards, the DFA tolerance analysis process can reach back into DFM:

- If tighter tolerances are required for function, they might necessitate the selection of higher precision manufacturing processes or materials that provide greater repeatability.

- Often, tolerance allocation can lead to the need for accommodating specific process and materials selections, such as shifting from gravity to pressure die cast, or implementing post-molding machining processes to achieve the necessary tolerances.

Integrated fasteners

There is no simpler and more effective design optimization than integrated fasteners. They greatly reduce part count and assembly complexity:

- Screw pillars molded to receive thread forming screws, or insert-molded with threaded receptacles remove the ‘two sides’ issue of threaded fasteners.

- Parts that snap together remove the fasteners and speed the assembly. Designers must take care if these are to be service removable.

Aggregating parts for assembly simplification improved performance

The process of aggregating multiple parts into a single part or a unified sub assembly is a key to efficient assembly. It’s not always the right thing to do because of necessary properties in aspects of the product, but there are tricks that can make a difference, when an imaginative approach is applied:

- Where two parts of the same or closely related materials are joined, can a change in the process selection or assembly order allow them to be made as one part?

- Where two joined parts must be divergent materials, can their connection be pushed back up to component supply by:

- Overmolding metal into plastic

- Integrating molded components with a live hinges, snaps, or kinematic mechanisms

- Overmolding rubber/rigid materials onto the first part

- Jointing dissimilar metal parts by welding, crimping etc.

- Where a housing contains the functional features of the product, that housing can be made to work harder by: integrating standoffs; enforce alignments to act as an assembly jig; integrate flexible mechanisms and living hinges such as case snap closures in place of screws etc.

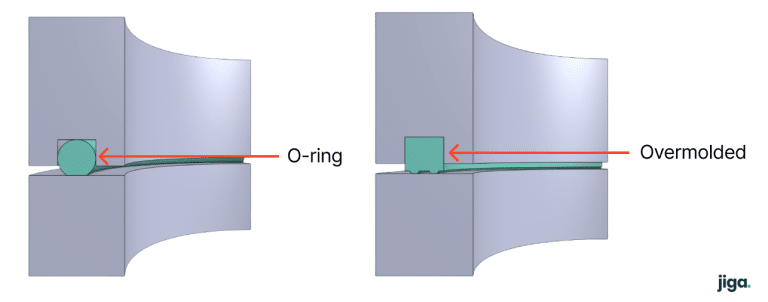

Replacing a separate O’ring with an overmolded seal can:

- Reduce assembly complexity

- Simplify stock and

- Improve seal reliability

This costs additional tooling stages and combines two related but unlike materials into a low labor stage that makes a better product outcome in a variety of ways.

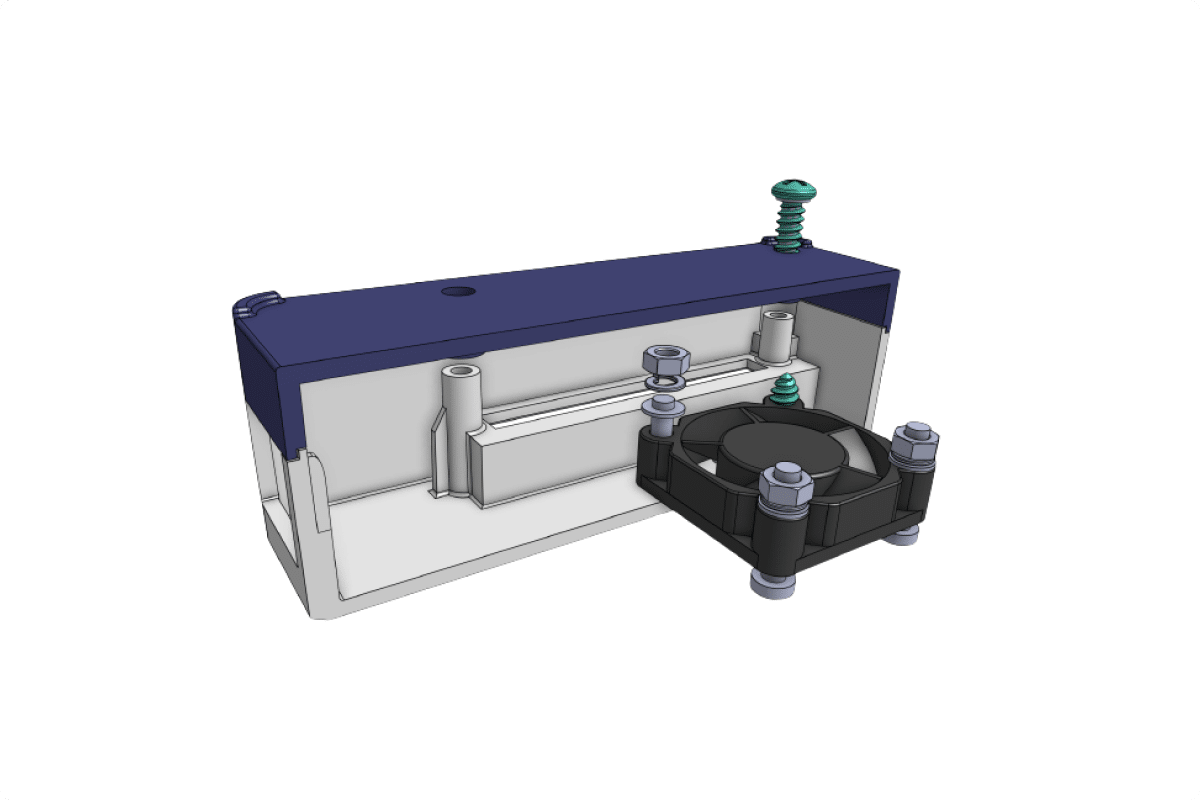

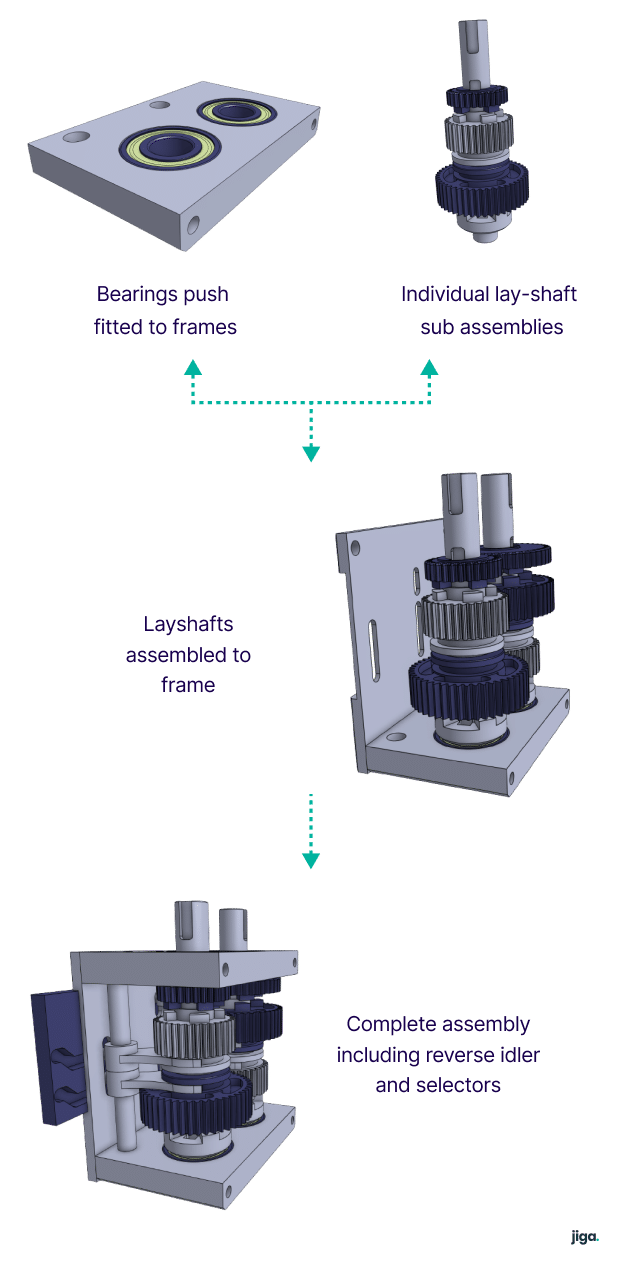

Design in modules/sub-assemblies

Where a product can be assembled as a series of modules that fit together simply, as a final assembly step, lower complexity can often be achieved:

- Modules that can be tested before final assembly allow for lower value-add before QA.

- Modules that can be pushed back into the component supply reduce the steps at assembly.

- Modularity, whether the modules are built on the assembly line or outsourced, reduces final assembly complexity and improves quality.

- Modularity in products that are built to be maintained is a key benefit, downstream.

- Modular design encourages re-use in new designs by creating ready made sub assemblies and functional blocks.

- When design changes are necessary, a modular design reduces the risks of new failure modes by having clearly defined module interface specifications.

Alan B.

Mechanical Engineer

"Hands-Down the Best Platform and Partner for Fast, Quality Parts"

Jiga is the best way to get the parts you need, when you need them.

Simplify Part Count

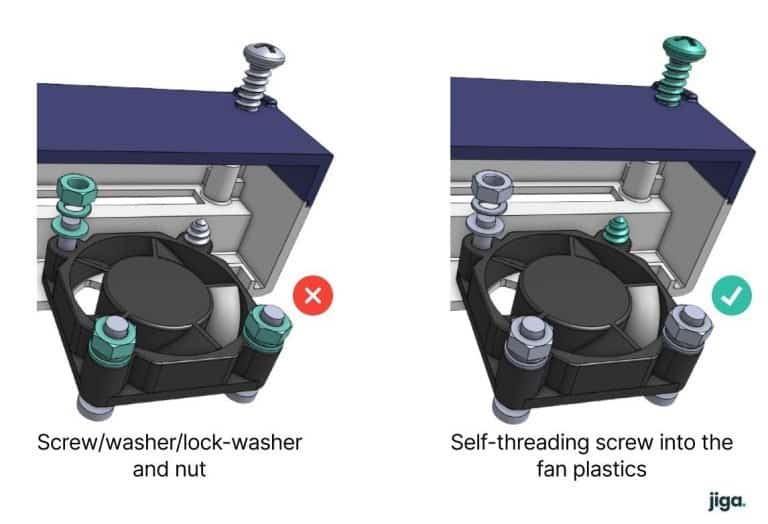

A key aspect of effective DFA design is to reduce wasteful and unnecessary part count:

- Use self assembling fasteners

- Reduce fastener type and installation complexity by using plastite threaded fasteners rather than nuts/bolts/washers

- Use the same fastener for multiple tasks, or use only length variations all with the same head type to reduce assembly tool-changes

Part symmetry (and asymmetry)

Part symmetry/asymmetry, which can also be read as ‘no alternative fitment possible’ or ‘fits correctly multiple ways’, can have benefits in assembly terms:

- Alignment and Orientation: Symmetrical parts reduce orientation effort during assembly, reducing the chances of misalignment.

- Lower Risk, Faster Assembly: Symmetry helps to identify correct orientations, reducing the risk of mistakes.

- Simplified Tooling and Fixturing: Symmetrical parts are less dependent on specialized fixtures or tooling as they have intrinsic self alignment.

- Design for handling: Try to make parts that are easy to handle and fit, integrate automation alignment features at the start, if you expect volumes to justify robotic assembly later.

While symmetry can offer advantages, not all parts or products can be symmetrical because of functional requirements, ergonomic considerations, or other design constraints. Striking a balance between symmetry and other design priorities is crucial. When designing with part symmetry in mind within a DFA framework:

- Identify Opportunities: Analyze the product design to identify components or features that could be made symmetrical without compromising functionality.

- Clear Orientation Markings: Even with symmetric parts, it’s helpful to include markings or features that help quickly determine correct orientation. Pin-socket features can clarify alignments.

- Sensor-Based QA: Automated QA stages that can detect the presence, absence or misalignment of components prevent or advise of incorrect assembly.

- Tooling and Self Jigging: Designing specialized tools and fixtures or integrating product features that only allow correct assembly positions can prevent incorrect assembly.

- Fail-Safe Design: Incorporating fail-safe mechanisms such as intrinsic next-stage barriers that halt the assembly process when an error has occurred.

Design for handling

Try to make parts that are easy to handle and fit, integrate automation alignment features at the start, if you expect volumes to justify robotic assembly later.

To emphasize this, Patrick Jreijiri, an experienced product designer, highlights, “Material handling. How easy is to move material? Are the parts too big?”

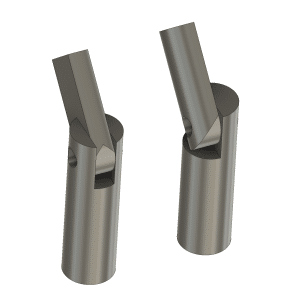

He also underscores the significance of tolerances, stating, “Another point is to reduce needs for tolerances. For example, if the design permits, make it where there is less needs for tolerances between parts. In the attached picture, the one on the left will require some gap between both arms and that will require additional 2 washers, and sometimes you get limited to the options of washers that are available to you. 0.2mm thicker and it won’t fit, 0.2mm thinner and it will be wobbly. The assembly on the right, is not limited by the same issues. You can even double the thickness of the washer and still be able to use it. That is very helpful if you are trying to consolidate parts.”

Jreijiri further explains, “For the assembly on the left you will have to align all parts and spacers before you can insert the bolt or pin. For the assembly on the right, you can assemble the bolt, part, washer and then insert it into the other part.”

Standardization

It is a guiding principle of good design – and therefore of effective DFA – to apply standard parts, sub-assemblies and methods/tools when developing a new product. This simplifies the transfer to production by making the assembly familiar and ramp-up ready where possible.

- Interchangeability: Standardized components can streamline though interchangeability in different products or assemblies.

- Simplified Assembly: When components are standardized, assembly processes and tools become more familiar, predictable and streamlined.

- Reduced Inventory Costs: Standardization minimizes the variety of components needed, leading to fewer parts in inventory and improving purchasing leverage and strengthening supplier relationships.

- Faster Development: Standardized parts can be reused across different product lines, reducing the time needed to design and develop new modules/sub-assemblies.

- Training Efficiency: Assembly line workers can become proficient at assembling standardized components, reducing the ramp-up time required for new products.

- Quality Control: Standardized components are subject to consistent quality control measures, leading to more predictable and reliable quality.

In implementing standardization according to DFA principles, various issues can make this process less onerous and more effective

- Component Selection: This applies to parts that can be standardized without adversely affecting functionality, quality or performance.

- Design Guidelines: Establishment of design guidelines/specifications for ‘stock’ components, (including dimensions, tolerances and interface features) makes their re-use in another context safer and more secure.

- Part Numbering and ERP software: Implementing a clear and organized part numbering system to track and manage standardized components is critical to effective control.

- Continuous Improvement: Reviewing and updating any standardized components and processes to reflect technology or supply chain changes is necessary to maintain relevance and optimal parts.

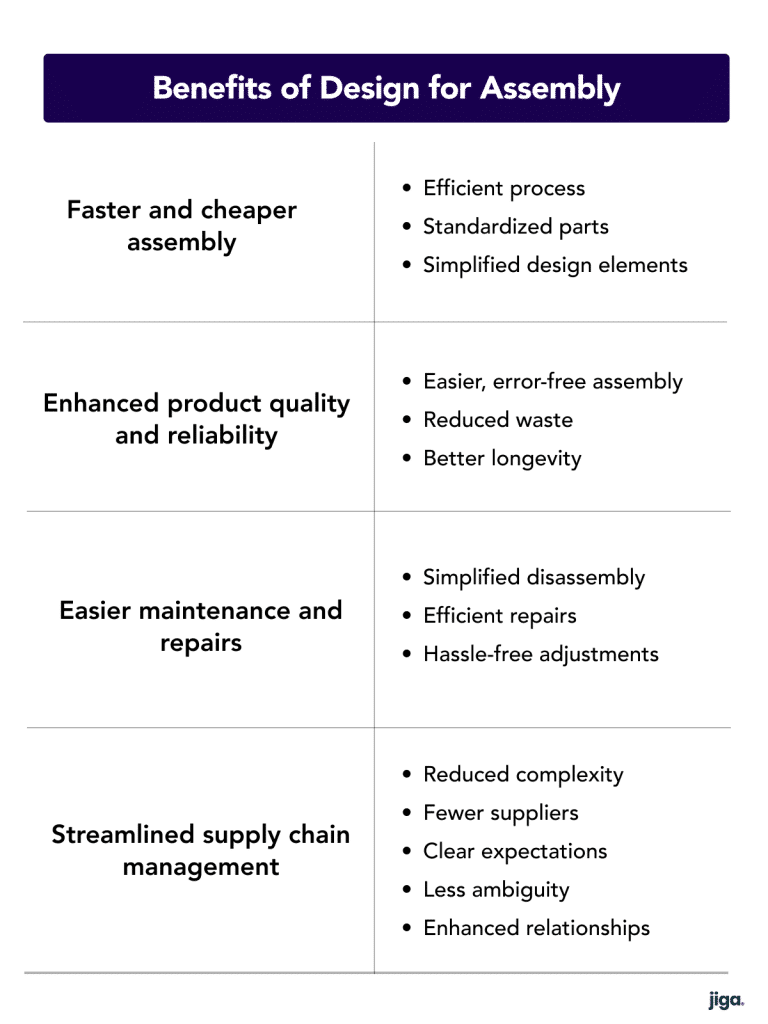

The Benefits of Embracing DFA

We are an organization that integrates the full range of product execution skills into our portfolio. We stand ready to assist you at any stage of your journey and we have a particular passion for the get-it-right from the start that is DFA. These are the ways we’d like to help you with this:

Reduced assembly time and costs

Design for Assembly (DFA) offers several benefits that directly contribute to reduced assembly time and costs in manufacturing processes. By focusing on simplification, standardization, and efficiency, manufacturers can optimize their processes and deliver high-quality products more effectively.

Enhanced product quality and reliability

Well executed DFA makes products easier and faster to assemble, with fewer errors and less rework. The knock-on effect of improved product quality is hard to measure, as it compares outcomes of a product that DFA prevented from being made, but the benefits are clear:

- Less scrap in production, as assemblies fail inspection and require rework or disposal.

- Fewer pre-damaged assembly outcomes that pass inspection criteria but fail in long term use.

Easier maintenance and repairs

A well designed and modular product that is built with highly standardized parts offers various benefits apart from the reduced cost of assembly:

- It will be easier to disassemble and evaluate for failures.

- Modules will be easier to replace and offer a higher value, lower stockholding overhead in an in-market repair service.

- Be easier to rework, when QA failures are detected.

George B

CTO

"Hands-Down the Best Platform and Partner for Fast, Quality Parts"

Jiga is the best way to get the parts you need, when you need them.

Streamlined supply chain management

A lower part count and greater standardization of components will reduce the supply chain complexity and potentially reduce the number of suppliers.

The influence of full module/part specifications and stringent-but-clear QA criteria will improve the chances of successful delivery, as suppliers will appreciate and understand clearly both the reasonableness and clarity of the inspection criteria through reduced ambiguity.

It can also contribute to improved supply chain management as relationships with suppliers become more integral and higher value to both parties.

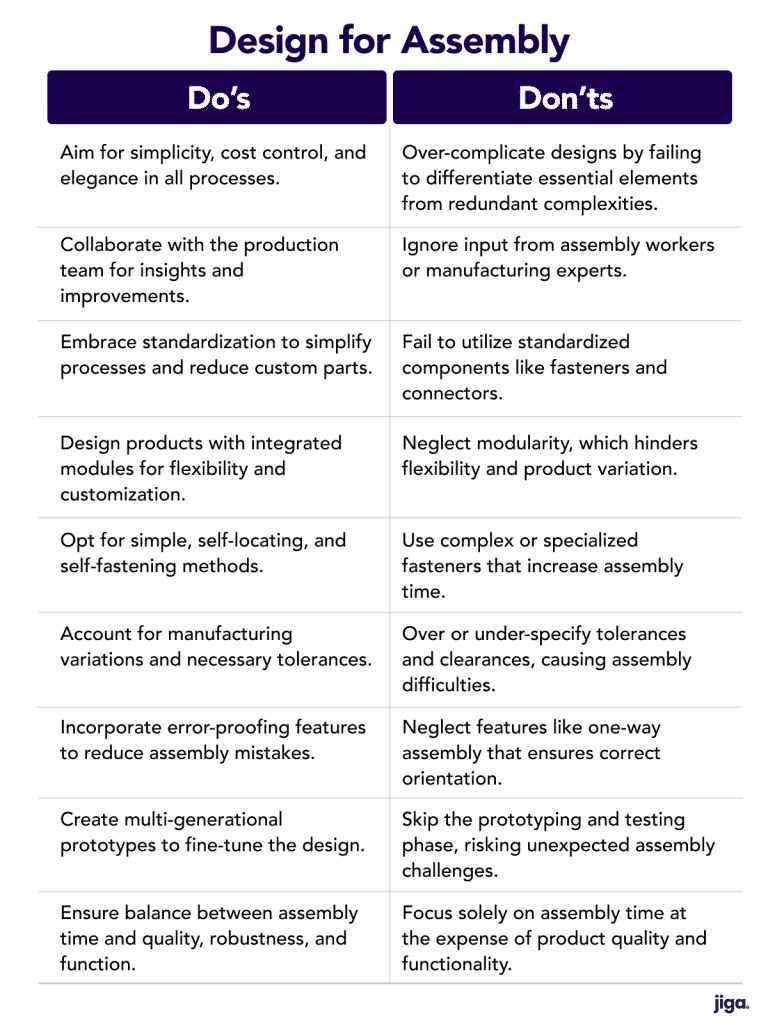

Common Mistakes in Design for Assembly (and how to avoid them)

DFA is a central plank of good product design that aims to simplify assembly processes and reduce manufacturing costs. There are common mistakes that designers too often make when implementing (or bypassing) DFA principles, particularly well defined in PCBa design and in quality control terms.

Over-Complicating Designs:

Designers sometimes fail to differentiate necessary and non-functional or redundant complexities in products and components. These can be poor choices of manufacturing process, cost savings with expensive consequences etc. Simplicity, cost control and elegance across all processes are prime targets

Ignoring Assembly Process Knowledge:

Designers can fail to consider input from assembly workers or manufacturing experts. Collaborate with the production team, to gain insights into challenges and opportunities for improvement.

Lack of Standardization:

Not utilizing standardized components like fasteners and connectors can lead to inefficiencies. Embrace standardization to simplify assembly processes and reduce the need for custom parts.

Neglecting Modularity:

Failure to incorporate modular design principles can hinder flexibility and customization. Design products with integrated modules/sub-assemblies allowing for parallel assembly and product variations with lower disruption.

Complex Fastening Methods:

Using intricate or specialized fasteners can seriously increase assembly time and complexity. Opt for simple, self-locating and self-fastening methods whenever possible.

Poor Tolerance Consideration:

Over (or under) specifying tolerances and clearances can lead to difficulties during assembly. Ensure components fit together properly by accounting for manufacturing variations and tolerances, but avoid tight controls that are not functionally necessary.

Focusing on Assembly Time:

If the design/DFA process focuses on assembly time to the detriment of quality, robustness and function then it serves to make the product fast to build but worse!

Neglecting Error-Proofing:

Error-proofing features can reduce assembly errors and rework. Features like one-way assembly or unique shapes that prevent incorrect assembly orientations can make the product much more reliable in assembly.

Failure to Prototype and Test:

Skipping the prototyping and testing phase can lead to unexpected (disastrous) assembly challenges and delays in mass production. Create multi-generational prototypes to identify potential issues and fine-tune the design before production.

Conclusion

There is no process that has a bigger impact on the transfer to production than DFA. Its value will be apparent in:

- Less rework and scrap in early production.

- Fewer early design and tooling iterations that delay ramp up.

- Better relations between design and manufacturing elements of the team.

- Less ‘design integrity’ discussions from the silo mentality.

- A better bottom line.

In simple terms, teams that operate in a seamless way from concept through to mass production will make better products, with less pain and delivered closer to planned schedule/budget. Teams that throw a design over the wall to production cannot compete.