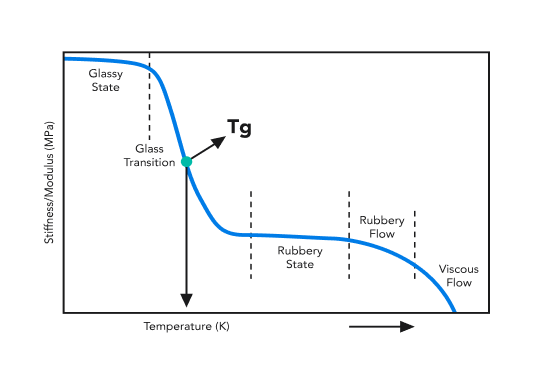

The glass transition temperature (Tg) of a thermoplastic is a pivotal thermodynamic and kinetic property of both amorphous and crystalline polymers. It defines the temperature at which a polymer transitions from a glassy, rigid state to a rubbery and more flexible state as its temperature rises.

Tg drives all of a typical polymer’s mechanical, thermal and processing behaviors in intrinsic ways. It is a fundamental property that allows us to predict, understand and manipulate the performance of polymer materials.

Importance of studying Tg in polypropylene (PP)

The Tg of polypropylene (PP) is of pivotal importance in a broad spectrum of applications, due to its central impact on the material’s mechanical, thermal, and processing properties.

The Tg of PP is generally relatively low, typically around -20°C to -0°C, varying with the tacticity/crystallinity of the polymer. This means that polypropylene generally exists in its ‘rubbery’ state, where polymer blocks/regions/chains can move against each other and accept distortion without fracture.

The main implication of this in processing terms is that the materials can be easily processed at moderate temperatures, by extrusion, injection molding and other manufacturing processes. This ease of processing contributes to cost-effectiveness and energy efficiency in processing.

- Polypropylene’s low Tg is valuable in packaging applications, enabling the material to retain its flexibility and toughness at relatively low temperatures. This is crucial for cold-stored food packaging.

- In the auto sector, the Tg allows components to withstand temperature fluctuations without embrittlement, making the polymer ideal for exterior buffers, interior trim and engine compartment liners/shields.

- Polypropylene fibers are applied extensively in textiles and nonwoven fabrics. The low Tg ensures that these materials remain flexible and durable at low service temperatures, necessary for cold-weather clothing, geotextiles and filtration media.

- Polypropylene is used in disposable medical devices and packaging, where flexibility and integrity at lower temperatures is relied upon for storage and transport of medical products.

- PP’s Tg makes it increasingly popular for various consumer goods, such as containers, toys and household items. It ensures that these remain tough and impact-resistant under all human-environment conditions.

- Polypropylene is utilized in agriculture for products such as greenhouse films, baler-twine and packaging. Its low Tg allows it to remain flexible and durable in outdoor environments with temperature fluctuations to zero Celcius or below.

Understanding Glass Transition Temperature

Definition and concept of Tg

Below the Tg, the inter-molecular structure of the polymer is glassy and crystalline. The polymer chains are constrained and relatively immobile. This makes the material stiff, relatively brittle and exhibit an incrementing elastic modulus and declining coefficient of thermal expansion as temperature falls. The polymer is in a frozen, disordered configuration.

As thermal excitation rises when Tg is approached, the materials molecular interactions gain enough thermal energy to weaken, become motile and able to slip. This eventually dissolves the rigid, glassy structure, and the polymer begins to soften and transition into a ‘rubbery’ state. The material becomes progressively more flexible and ductile and develops a lower elastic modulus as the Tg range is crossed. The polymer also shows increase in volume as it transitions to this state

Significance of Tg in determining material properties

Several important aspects of polymers are influenced by the Tg:

- The Tg is a critical parameter in polymer processing. Processing a polymer above its Tg allows it to flow and be molded or shaped.

- It influences a polymer’s stiffness, brittleness and impact resistance. Polymers above Tg are more ductile.

- The Tg also influences a polymer’s long-term stability and performance, as materials strained when above their Tg are liable to undergo creep, relaxation and dimensional changes.

- Understanding the Tg is significant for storing polymers, to prevent cold crystallization or embrittlement during low-temperature storage.

- Engineers and designers use the Tg as a criterion when selecting polymers for specific applications, especially those involving temperature extremes.

Factors affecting Tg

Tg in polymers is manipulable by means of various factors, understanding which is essential for predicting and exploiting a polymer’s properties.

- Different polymers have divergent Tg values. The molecular structure and chemical composition of the polymer play a huge role in determining its Tg. Amorphous polymers have higher Tg values compared to semi-crystalline ones.

- Polymer chains with greater flexibility and freedom of movement tend to have lower Tg values. Factors such as the length of polymer spines and their tacticity can significantly affect chain mobility and thus Tg.

- In principle, higher molecular weight polymers have higher Tg values. This results from longer chains being more resistant to molecular movement and requiring higher energy to transition to the softer state.

- The type and nature of chemical or functional groups in the polymer can significantly influence Tg. Polarized groups in the polymer backbone increase Tg, as inter-chain attraction creates quantifiably stronger connecting forces between chains.

- Copolymers – those whose structure is composed of two or more monomer types – commonly have Tg values that are directed by the composition of the copolymer. Changing the ratio between monomers facilitates significant control over the Tg, resulting in highly adjustable properties.

- In some cases, polymers can undergo curing or cross-linking processes, which can raise their Tg values. This can be achieved through chemical additives and in some cases by irradiation. This cross-linking restricts molecular mobility and increases the polymer’s thermal stability, making the material behave very differently from the non cross-linked equivalent.

- The incorporation of plasticizers, fillers, or other additives can modify a polymer’s Tg and allow it to be tuned for optimal properties. Plasticizers tend to lower Tg by increasing chain flexibility and motility, while fillers may increase Tg due to their imposition of greater rigidity which reduces motility.

- The conditions under which a polymer is processed or molded can heavily influence Tg. Rapid cooling can raise the Tg by freezing a ‘stressed’ molecular structure. This effect is transient in that approaching Tg at a later stage will result in relief of this stressed molecular structure and reversion to normal. Annealing during processing can reduce the final Tg, by allowing a fully stress relieved structure to develop.

- High processing pressures can alter a polymer’s Tg. This effect is unpredictable and requires experimental validation, as the elevated pressure can raise OR lower Tg, depending on the polymer, the additive state, the rapidity of cooling etc.

- Absorption of moisture can significantly affect Tg in hygroscopic polymers such as some nylons (PA). Water molecules can disrupt polymer-polymer interactions by acting as softening and lubrication agents and by causing swelling that disrupts inter-chain connectivity, leading to a lower Tg.

Understanding these diverse and complex factors is crucial for engineers and scientists working with polymers. Plentiful opportunities exist to tailor a polymer’s properties by adjusting several parameters to meet specific performance needs.

Shaked S

Purchasing Manager

"A consistent 20% cost reduction on custom parts"

Jiga is the best way to get the parts you need, when you need them.

Factors Influencing Polypropylene Glass Transition Temperature

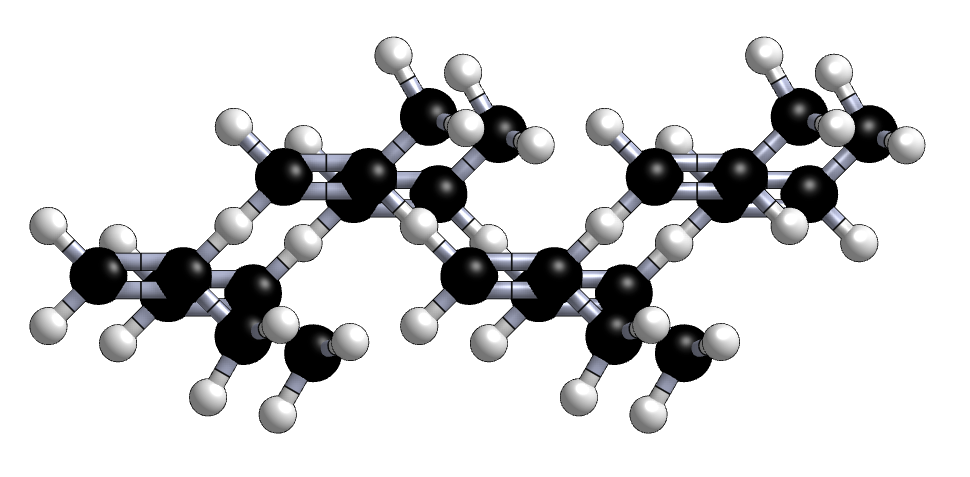

Molecular structure of polypropylene

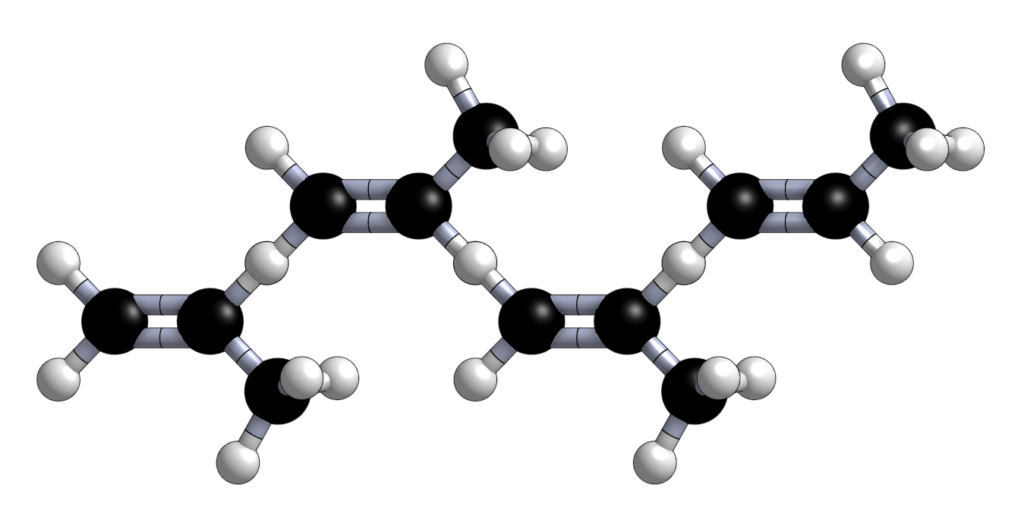

Like all thermoplastics, PP consists of strongly bonded and elastic long chain molecules that are only weakly attached to each other. This makes a weakly coupled matrix when the chains are short, staggered or branched and stronger, more crystalline behaviors when the chains are long and smooth, as they’ll align and couple more closely.

The materials mechanical properties relate more to the chain strength, whereas the thermal properties are much more closely affected by

The molecular structure of polypropylene has a significant influence on its Tg.

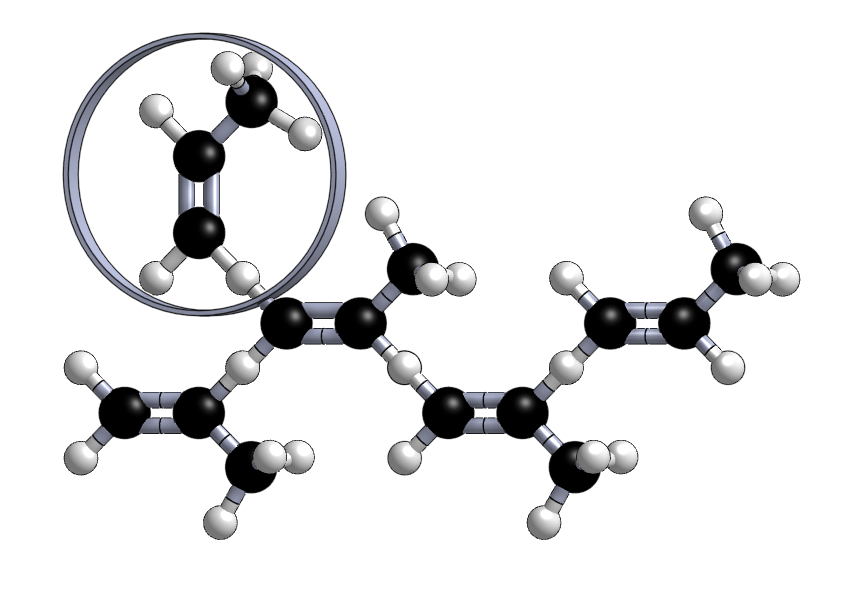

- Tacticity and stereochemistry: Polypropylene can exist in three different forms, based on the arrangement of its methyl groups (CH3) along the polymer chain. Isotactic PP, with all methyl groups on the same side of the polymer chain, has the highest Tg, as the predictable ‘smoothness’ of the polymer chain allows close packing and increased crystallinity. Atactic PP, where methyl groups are randomly distributed, has a lower Tg as randomness reduces chain proximity. Syndiotactic PP, with alternating methyl group positions, falls between isotactic and atactic PP in terms of Tg as local and limited zones of closer proximity between chains can develop.

Tacticity is the measure of order or disorder in the molecular structure of the chains, where stereochemistry is the measure of the bulk-effect of tacticity in enabling more or less order and crystallinity in the overall structure.

The molecular structure of polypropylene has a significant influence on its Tg.

- Tacticity and stereochemistry: Polypropylene can exist in three different forms, based on the arrangement of its methyl groups (CH3) along the polymer chain. Isotactic PP, with all methyl groups on the same side of the polymer chain, has the highest Tg, as the predictable ‘smoothness’ of the polymer chain allows close packing and increased crystallinity. Atactic PP, where methyl groups are randomly distributed, has a lower Tg as randomness reduces chain proximity. Syndiotactic PP, with alternating methyl group positions, falls between isotactic and atactic PP in terms of Tg as local and limited zones of closer proximity between chains can develop.

Tacticity is the measure of order or disorder in the molecular structure of the chains, where stereochemistry is the measure of the bulk-effect of tacticity in enabling more or less order and crystallinity in the overall structure.

- The presence of branches or side chains in the polymer structure can lower Tg. Branching disrupts the regular packing of polymer chains, reducing intermolecular forces and mobility. This relates to tacticity, but longer side branching has a more significant effect than the regularity of tacticity.

- Longer (low branched) polymer chains in PP tend to have higher Tg values. Longer chains have more entanglements and interactions, leading to increased rigidity and a higher Tg. Polypropylene chain lengths can be varied both by initial polymerization processes and by post-polymerization catalytic reactions that than both create longer chains (raising Tg) and more side branching (lowering Tg)

- Copolymerizing propylene with other monomers can affect the Tg. The choice and proportion of comonomers can alter the polymer’s molecular structure and Tg by inducing greater crystallinity in regions, which acts as a binding that increases Tg. Copolymers can also reduce the Tg when the secondary addition is a more side branched polymer type..

The Tg of polypropylene is hugely influenced by its additive state and moderately by its molecular structure, which allows for aggressive adjustment of properties with various degrees .

Isotactic PP, with a highly ordered and crystalline structure, typically has the highest Tg among the different forms of otherwise unmodified PP around ~0°C and a melting point of ~180°C. Atactic PP has a Tg of around -15°C and melting point of 160°C.

However, addition of 60% glass fill in commercial grade isotactic PP can elevate the Tg to well over 100°C, while altering the liquefaction temperature very little.

Understanding these structural factors is essential for tailoring the properties of PP to meet application requirements.

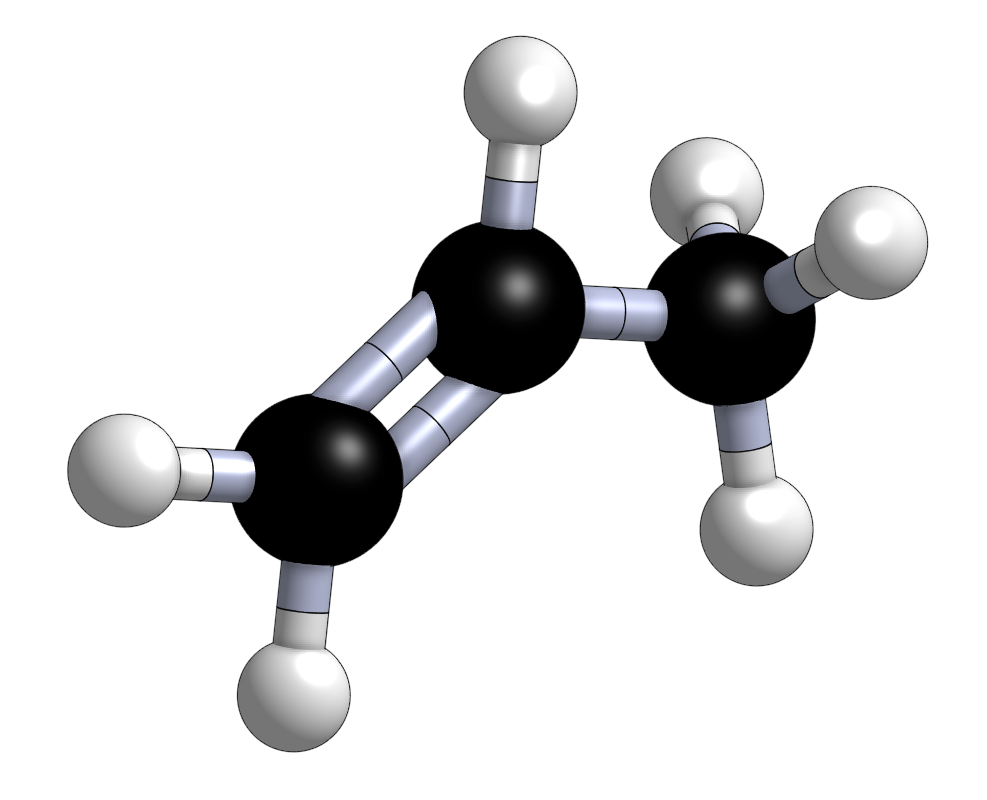

Molecular weight and its impact on Tg

The molecular weight of PP is a direct result of the chain length, or backbone. This is the Carbon-Carbon single bonds and chain length is a tunable characteristic of the manufacturing process. It’s worth noting that a double bond (C=C) results in a stronger polymer chain, where PP has a mix of single Carbon bond (C-C) and double bonds. Chains are as strong as their weakest link.

PP can be made in a range of molecular weights ranging from 10k to 40k grams per mol. This significantly affects a wide spectrum of thermal and mechanical properties.

The molecular weight of polypropylene (PP) has a marked effect on the resulting Tg.

- As the molecular weight (chain length) of PP increases, its Tg tends to rise. Longer polymer chains have more entanglements and greater/more diverse intermolecular attraction forces. These entanglements restrict relative molecular motion and inter-chain elasticity, making it more difficult for the polymer to transition from a glassy to a rubbery state. Consequently, high molecular weight PP typically has a higher Tg, and it is more rigid and brittle at lower temperatures.

- Lower molecular weight PP has shorter polymer chains and fewer entanglements. It therefore has a lower Tg, making it more flexible and resilient at lower temperatures.

- A varied distribution of molecular weights in a PP sample, known as polydispersity, can also affect Tg. A wide distribution of molecular weights can lead to a broader Tg range, as different polymer chains within the sample may have different Tg values. This allows localized initiation of the transition in lower molecular density regions to commence prior to the onset in longer chain regions.

- During polymer processing, the molecular weight of PP can change due to factors like temperature and shear forces. High-temperature processing can lead to chain length degradation, reducing Tg.

- The addition of copolymerizing agents can influence the molecular weight and tacticity of the net material, which in turn affects its Tg. Comonomers can disrupt the regularity of the polymer chain and lower the Tg, where block copolymers can induce regional increases in crystallinity that either raises Tg or extends its range.

Crystalline region and its effect on Tg

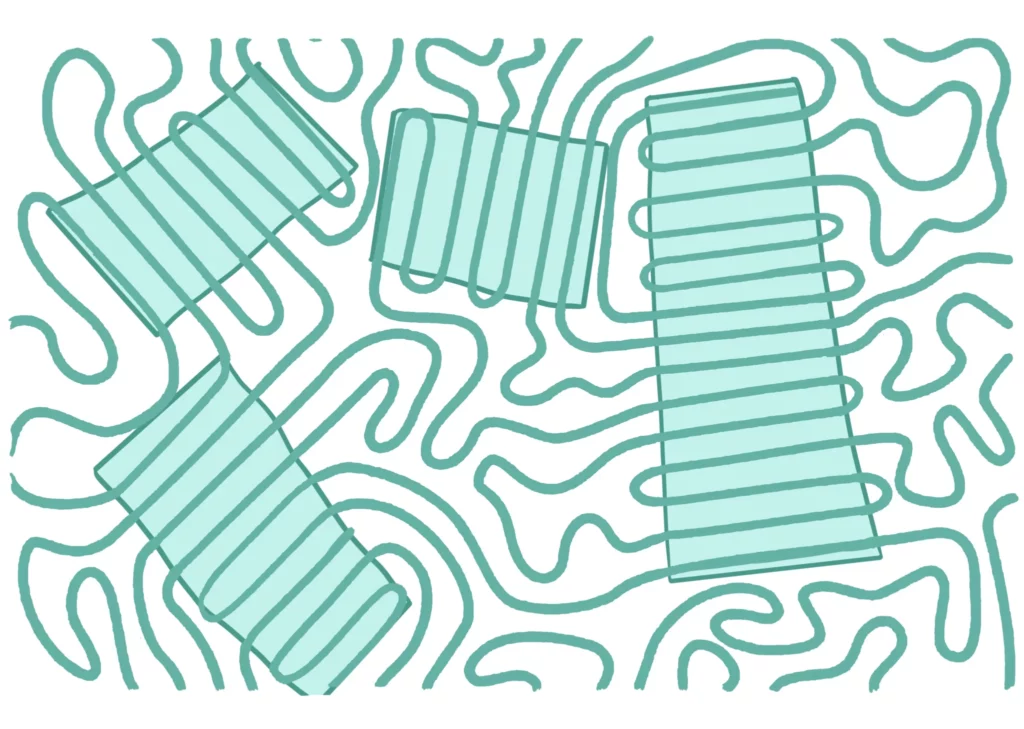

The presence of crystallinity in PP – either localized or generalized – has a significant influence on Tg. PP is a semi-crystalline polymer, consisting of both amorphous (non-crystalline) and crystalline regions within its molecular structure, but the proportions vary considerably.

- The amorphous regions of PP contribute strongly to the glass transition temperature, or its onset. Amorphous regions are characterized by polymer chains that are disordered and have greater molecular mobility. As temperature increases, these chains gain enough thermal energy to transition from a glassy, rigid state to a rubbery, more flexible state, which corresponds to the Tg of the amorphous phase. The Tg of these amorphous regions typically lies in the -20 to -10°C range.

- Crystalline regions in PP are highly ordered and rigid due to the regular packing of polymer chains. While the crystalline regions affect the melting temperature considerably, the Tg of the amorphous regions overwhelmed the Tg significance of the crystalline regions.

Atactic polypropylene and its influence on Tg

Atacticity, which refers to the lack of a regular or ordered arrangement in the placement of side groups or substituents along the polymer chain, has a significant impact on the glass transition temperature (Tg) of polypropylene (PP).

As the tacticity in PP decreases (increasing atacticity), the Tg tends to decrease as the material is more amorphous. Atactic PP has a more disordered and amorphous structure compared to isotactic PP (which has a highly ordered structure). This leads to a greater degree of molecular mobility and weaker inter-chain bonding, easing the transition from a glassy, rigid state to a rubbery.

Atactic PP exhibits increased chain (and therefore bulk material) flexibility due to the lack of regular stereoisomerism.

Block copolymer and its impact on Tg

Block copolymerization can greatly influence the Tg of PP when it is incorporated into the polymer structure. Block copolymers consist of two or more different blocks of polymers that are chemically bonded together. When the copolymer agent is more crystalline in nature than the PP, it can add stiffness and strength, while only moderately affecting Tg and processing properties. As with the effects of tacticity, block copolymers tend to have the Tg of their most amorphous regions – but the melting point can be more elevated by the additional of more crystal regions.

Block copolymerization can be a very effective tool for tuning properties significantly, while only moderately altering the Tg of the base material.

The composition and arrangement of the blocks in the copolymer play a crucial role in determining the Tg. For example, if one block is composed of highly flexible monomers while the other block is composed of more rigid monomers, the resulting block copolymer may exhibit a Tg that falls between the Tg values of the individual blocks. The overall Tg of the copolymer will depend on the relative proportions and properties of the blocks.

- Block copolymers often exhibit phase separation, where the different blocks form distinct phases with varying degrees of order or crystallinity. These phase-separated regions can influence the overall Tg of the material. In some cases this can lead to unique thermal properties.

- The tacticity of the individual blocks within a block copolymer can also affect the overall Tg. For instance, if one block is predominantly atactic and the other is isotactic, the Tg is likely to result primarily from the atactic regions properties.

- The flexibility of the polymer chains in each block, and their compatibility with one another, can impact the Tg. If one block is more flexible and amorphous while the other is rigid and crystalline, the resulting Tg may be a complex combination of the individual block properties and can become an extended range of temperature rather than a narrow and precise transition.

Cross-linking and Tg

Cross-linking in PP can have a significant effect on Tg and overall thermal properties. Cross-linking involves creating covalent bonds (cross-links) between polymer chains, which changes in the material’s structure and behavior. These bonds are achieved by use of a catalyst or a chemical bonding agent in the polymer. A catalytic reaction triggers direct atomic coupling by local-induced polarization (freeing valencies in the chains to interact covalently) or by adding a bridging agent that can attach to pairs of chains for similar effect.

- Cross-linking generally raises the Tg of PP. When cross-links are introduced between polymer chains, they restrict molecular mobility within the material, requiring greater energy for the polymer to transition to a rubbery, flexible state. Cross-linked PP becomes stiffer/stronger compared to non-cross-linked PP.

- Cross-linking enhances the thermal stability of PP. The covalent bonds formed through cross-linking provide resistance to thermal degradation and chemical attack, allowing the material to maintain its structural integrity at higher temperatures.

- Cross-linked PP may exhibit reduced crystallinity and an altered melting point compared to non-cross-linked PP. The cross linking can raise the melting point of amorphous PP by increasing inter-chain coupling. It can lower the melting point of atactic PP by disrupting the formation of crystalline relationships between chains.

- PP with moderate to extensive cross-linking exhibits improved dimensional stability, making it less susceptible to shrinking or warping. This is particularly advantageous in applications where tight tolerances and shape retention are critical and commercialization of this capability has essentially allowed PP to be used as a near-engineering grade polymer..

- The trade-off is that cross-linked PP tends to be harder, more brittle and offer lower flexibility and fatigue resilience than non-cross-linked PP, especially at room temperature.

George B

CTO

"Hands-Down the Best Platform and Partner for Fast, Quality Parts"

Jiga is the best way to get the parts you need, when you need them.

Measurement and Determination of Polypropylene Glass Transition Temperature

Techniques used to measure Tg

Several techniques are commonly used to measure Tg of polymers. Each technique has its advantages and limitations, and the choice of method depends on the specific polymer, sample form, and experimental requirements. These are; differential scanning calorimetry (DSC); dynamic mechanical analysis (DMA); thermomechanical analysis (TMA); dilatometry; dielectric analysis (DEA); pyrolysis-gas chromatography (Py-GC); modulated DSC (MDSC); thermo- gravimetric analysis (TGA); rheological techniques; dielectric thermal analysis (DETA).

Measurement of the Tg of PP is critical in optimizing the processing of the material. Reduced heating saves cost and reduces the potential for molecular damage that can rapidly degrade the properties of the material and finished products.

- Differential scanning calorimetry (DSC) is one of the most widely used techniques for measuring Tg. It involves heating a polymer sample while monitoring the heat flow to detect changes in heat capacity associated with the glass transition. The Tg is determined from the inflection point of the heat flow curve. DSC is precise and provides information about the heat capacity change at Tg.

- Dynamic mechanical analysis (DMA) measures the mechanical properties of a polymer as a function of temperature, frequency, or time. It can determine the storage modulus and loss modulus, from which Tg can be derived. DMA is particulalry utilized for characterizing the viscoelastic behavior of polymers.

- Thermomechanical analysis (TMA) evaluates changes in the dimensions of a test piece as it is heated or cooled. Tg is derived from the onset and ending or non-linear behavior at the Tg transition. TMA is applicable to thin films and coatings.

- Dilatometry, which is similar to TMA and measures the change in volume or length of a sample as a function of temperature. Tg is derived from the inflection point of the thermal expansion curve.

- Dielectric analysis (DEA) measures the dielectric properties of a polymer, such as permittivity and loss factor, as a function of temperature. Tg is typically identified by a peak in the loss factor curve.

- Dielectric thermal analysis (DETA) combines dielectric and DSC measurements to analyze the dielectric behavior and heat flow simultaneously, facilitating a more nuanced characterization of Tg.

- Pyrolysis-gas chromatography (Py-GC) involves heating a polymer sample to high temperatures in an inert atmosphere and analyzing the volatile products released. Tg can be estimated from changes in the pyrolysis profile with temperature.

- Modulated DSC (MDSC) combines DSC with a sinusoidal temperature modulation to separate reversing and non-reversing heat flows. This technique can provide more accurate Tg measurements, especially for complex polymers.

- Thermo-gravimetric analysis (TGA) is particulalry used for evaluating mass-loss due to decomposition, but it can indirectly provide information about Tg by monitoring changes in the rate of weight loss as the temperature increases.

- Rheological approaches like creep and stress relaxation tests, can provide information about the viscoelastic behavior of polymers near Tg. Changes in mechanical properties logged through a heating cycle can be used to derive Tg.

- Thermal expansion or dilatometry measures the change in volume or length of a polymer sample as it is heated or cooled. Tg is identified by the sudden onset of non-linearity in the rate of expansion or contraction.

Choice of technique depends on the specific polymer, sample size and the desired level of precision. It is common to use multiple techniques to cross-validate Tg measurements, especially for complex polymer systems.

Importance of accurate Tg determination

Precise knowledge of Tg is essential in polypropylene (PP) applications for several reasons, as it is central to effective and minimally-damaging processing of the material by all melt-forming or plastic deformation processes.

It is also critical to component performance, in that usage that approaches the transition to the rubbery state by heating will severely alter the mechanical properties of the material.

In the case of PP, the Tg is generally low, typically between -20 and -10°C, so care is only required in cold applications, where the material may be excessively stressed while in its chilled and essentially more brittle state.

Understanding Tg has very high value implications in material selection, component design and functional optimization;

- Tg is a critical parameter for material selection in PP applications. It helps engineers and designers choose the appropriate material grade for the intended operating temperature range.

- Understanding Tg is essential if the dimensional stability of PP parts is to be assured throughout the operational temperature range of the product.

- Knowledge of Tg allows optimized processing conditions for PP, determining suitable melt temperatures and cooling rates during molding or extrusion processes.

- Tg is a key factor in predicting the durability and long-term performance of PP components. Parts operating above their Tg are liable to creep, stress relaxation, and reduced mechanical properties over time, which must be designed for. Alternately, parts that transition into temperatures below their Tg will suffer stiffening and embrittlement, which may be catastrophic if not allowed for.

- Tg influences polymer’s chemical resilience and susceptibility to environmental stress cracking. Knowing Tg serves in evaluating how PP will react to aggressive chemical environments.

- In applications involving food contact, pharmaceuticals, or medical devices, knowledge of Tg is imperative for compliance with safety and regulatory expectations.

- Precise Tg data enables predictive analysis of the reliability and integrity challenges to PP products under stress conditions.

- By understanding Tg and its impact on material behavior, manufacturers can optimize material utilization, reduce waste and control manufacturing costs.

Effects of Polypropylene Glass Transition Temperature

Thermal expansion and its relationship with Tg

The relationship between thermal expansion and Tg in PP is critical in understanding how the materials behave under cyclic and periodic temperature influences. It drives affects expansion significantly, increasing it as Tg is approached and exceeded.

The relationship between thermal expansion and Tg in PP is characterized by a transition in the property as the material transitions through theTg range. Below Tg, PP is relatively dimensionally stable with low thermal expansion. As the temperature approaches and exceeds Tg, the thermal expansion increases. This range of behavior results directly from the increated molecular/chaim motility that occurs as the inter-chain coupling forces begin to weaken.

Understanding this relationship is important for designing and engineering PP components to accommodate/tolerate dimensional changes over a range of operating temperatures.

Physical properties influenced by Tg

The Tg of PP significantly influences several physical properties of the material.

- Hardness is reduced as Tg is approached.

- Flexibility increases sharply at or above Tg.

- Dimensional stability – both mechanical and thermal – is reduced above Tg. This can be apparent as heat distortion and creep as well as unstressed thermal expansion.

- Impact resistance increases significantly as Tg is exceeded.

- Chemical sensitivity can rise as the material heats, though this may only correlate loosely with Tg.

- Thermal conductivity of PP falls as temperature rises – until a sudden increase that occurs near liquefaction.

Molecular mobility and Tg

TheTg of PP is intimately linked to the molecular mobility of the polymer chains. Understanding the relationship between molecular mobility and Tg is therefore crucial for apprehending the behavior as temperatures vary.

The material essentially exists in 4 states, related to rising temperature;

- Below the Tg the structure is bound, rigid and glassy. The degree of crystallinity varies with atomic structure/tacticity and chain length but the chains or at their most coupled and rigid.

- In the transition temperature range, the more amorphous regions are first to begin to loosen in inter-chain coupling, and as temperature rises the more crystalline regions will follow suit. The Tg range can be wider or narrower because of a variety of material properties and additive types. This is the transition from fully glassy to fully rubbery in nature.

- Above the Tg range, the bonds have weakened and they begin to fail as temperature rises.

- At the onset of liquefaction, the inter-chain bonds have essentially broken down fully and the material becomes an increasingly inviscid liquid as temperature rises.

Impact of Tg on injection molding process

The Tg of PP is significant in the injection molding process, impacting various aspects of the manufacturing process.

It is normal to inject/extrude PP at a temperature that exceeds the upper boundary of Tg but is often considerably below the total liquefaction temperature. This prevents polymer damage, excessive shrinkage during cooling and a number of other manufacturing properties.

Tg has profound influence on the molding process and must be accounted for in adjusting molding parameters;

- Below Tg, the polymer is in a glassy state and has limited molecular mobility. For appropriate flow and mold filling, the melt temperature should be above Tg to allow the polymer chains to become more mobile and viscous.

- Tg defines the ‘processing window’ for temperatures within which injection molding/extrusion should occur. Low temperatures result in poor flow, incomplete mold filling, and increased mold filling pressures. Temperatures too far above Tg can lead to excessive cooling shrinkage and part distortion.

- Mold cavity temperature is crucial in injection molding. Proper mold temperature control facilitates effective filling and is essential to achieve good part quality, minimize warping and dimensional stability. PP is commonly molded in tools running at 80°.

- The cycle time for injection molding is partly defined by Tg. Excessive heating can lead to longer cooling times to achieve proper part solidification, increasing machine time and part costs.

- Temperature greatly affects the shrinkage behavior of PP. Parts molded at too high a temperature exhibit higher levels of shrinkage and warping as they cool and solidify. Injection between 220 and 280° is common.

- The choice of gate location and design can be influenced by Tg. A gate located at the thickest section of a part may require higher injection pressure to ensure proper filling when molding below Tg. Proper gate design can help reduce flow resistance.

- The cooling rate during (after) the injection molding process impacts the final part properties. Slower cooling rates can allow the polymer chains to relax and align, potentially affecting the crystallinity and mechanical properties of the molded parts.

- Melt-flow behavior must be considered in gate positioning and design, to optimize the cavity filling process, minimize turbulence and achieve appropriate cycle times.

Comparison with Other Polymers

Comparison of Tg between polypropylene and other polymers

The Tg value and range vary widely among divergent polymers, but remain critical and defining parameters that influence material behavior and properties in intrinsic ways.

- Polypropylene – Tg for PP typically ranges from approximately -10°C to -20°C (14°F to -4°F), which is low amongst thermoplastics and makes PP a tough and resilient material at depressed temperatures.

- Polyethylene (PE) – Tg for polyethylene is lower than for PP and can range from around -120°C to -80°C (-184°F to -112°F) depending on molecular weight. Polyethylene is ideal for low-temperature applications requiring flexibility and low-temperature resistance.

- Polystyrene (PS) and ABS – Polystyrene has a Tg of around 100°C (212°F) and the various copolymers that are based upon it are in a similar range. It is best used where transparency and rigidity are keys, especially at room temperature and above. It is a brittle material in its unalloyed form.

- Polyvinyl Chloride (PVC) – PVC has a Tg in the range of 70°C to 85°C (158°F to 185°F). This delivers good dimensional stability and rigidity at room temperature and above and allows most grades to handle temperatures above 100°C.

- Polyethylene terephthalate (PET) – PET has a Tg of around 76°C (169°F), making it optimal for applications where dimensional stability and stiffness are important at moderate temperatures.

- Polycarbonate (PC) – PC has a Tg of approximately 145°C (293°F), making it suitable for applications requiring excellent impact resistance, clarity and high-temperature tolerance.

- Polyamide (Nylon) – The Tg of various nylon grades can vary, typically falling within the range of 40°C to 80°C (104°F to 176°F). Nylons are renowned for their mechanical strength, toughness, and good chemical resistance but Tg can be affected by their tendency to absorb significant amounts of moisture.

- Polyurethane (PU) – The Tg of polyurethane varies widely depending on chemical composition, but it can range from -60°C to 120°C (-76°F to 248°F). PU can be tailored to meet specialized application demands.

It’s important to note that Tg values vary widely, based on the specific grade, formulation, additives and processing conditions of each polymer. This allows engineers and designers to specify polymers that are optimal for their intended applications.

Differences in Tg based on molecular structure

Tg variation with different polymer chains

The glass transition temperature (Tg) can vary significantly among different polymers due to variations in their chemical structure, molecular chains, additives and interactions. Care is required in exactly specifying; the polymer type/family; the molecular weight (chain length); tacticity; branching; crosslinking and more.

Material suppliers as information sources can be invaluable, as can material data sites that catalog a spectrum of manufacturers and grades in searchable forms.

A brief analysis of polymer chain form/length effects on PP properties is offered here;

- Homopolymers (single form and simple chains) with linear, non-branched structure have Tg values that are influenced by factors such as chain length (molecular weight), additives and chemical composition. Longer chains tend to have higher Tg values, while shorter chains lower.

- Polymers with branched chains have more complex molecular structures which reduce inter-chain proximity and interaction. In many cases, branching lowers Tg by disrupting the regularity of the polymer chains.

- Cross-linked polymers have covalent bonds connecting polymer chains into a closely coupled 3D matrix. Cross-linking can significantly increase Tg by restricting chain mobility and introducing strong covalent bonds that resist thermal motion.

- Some polymers have cyclic or ring-shaped chains. These polymers can have higher Tg values due to the constrained geometry of the cyclic chains, which limits chain mobility.

- Copolymers with branched chains that contain different monomers may have Tg values influenced by the specific structure and arrangement of the branches. The presence of different monomers can lead to phase separation and affect Tg in unpredictable ways.

- Block copolymers consist of segments of different monomers connected in blocks. The arrangement of these blocks greatly influences Tg, with each block contributing its own Tg value and the ‘weaker’ or more amorphous blockers defining the onset of Tg. Phase separation between the blocks can also affect material behavior.

- Grafted polymers have side chains or branches attached to a main polymer backbone. The presence and nature of these side chains can affect Tg by introducing steric hindrance and changing molecular interactions.

- Tacticity influences Tg – isotactic polymers, where side groups are consistently oriented on one side of the chain, may have higher Tg values than atactic polymers with randomly oriented side groups.

- Polymers with conjugated double bonds in their chains, such as conjugated polyenes, can have unique electronic and thermal properties. Conjugation can influence Tg by affecting the degree of chain planarity and delocalization of electrons.

Patrick J

Product Design

"Game changing in the online manufacturing space"

Jiga is the best way to get the parts you need, when you need them.

Applications and Industrial Significance

Industrial uses of polypropylene with respect to Tg

PP is a versatile polymer with various industrial uses and it is used in huge quantities in various forms/grades. Tg plays a significant role in determining its suitability for different applications and the fine detail of selection can be driven in large part by this property or by its desired consequent effects on properties.

PP is used widely in; food containers; packaging films; automotive components; medical devices; woven and non-woven textiles; battery components; agricultural consumables; industrial chemical containers; consumer goods and toys and more.

Products that require high temperature performance and toughness benefit from the low Tg. Products that require high dimensional stability and stiffness use additives to drive up the Tg in many cases.

- Packaging materials:

PP’s low Tg makes it an excellent choice for packaging materials. It remains stiff enough and tough at room temperature, providing structural support and protection for packaged goods.

Common applications include food and cleaning product containers, beverage bottles, caps, and closures.

- Films and sheets:

PP films and sheets are used in various industrial applications due to their clarity, flexibility, and ease of processing.

Low Tg allows PP films and sheets to maintain their structural integrity and dimensional stability, even at lower temperatures.

- Automotive Components:

PP is used in automotive interior components such as dashboards, door panels, and interior trim. Its low Tg ensures that these components remain sufficiently rigid but highly durable under normal operating temperatures in vehicles.

- Medical Devices:

PP is employed in medical devices like syringes, medical tubing, and containers.

Its low Tg ensures that these devices remain stable and tough during use.

- Textiles:

PP fibers are used in woven and non woven textiles for various applications, including carpeting, geotextiles, filters, diapers, wipes and upholstery.

Low Tg contributes to toughness and flexibility for these textile products.

- Battery Components:

PP separators are used in batteries to prevent short-circuits between electrodes.

The low Tg of PP ensures that the separator remains stable and mechanically robust within the battery, even when charging or discharging results in elevated temperatures.

- Industrial Containers:

PP containers and crates are widely used for storage and transportation of goods. The low Tg helps maintain the structural toughness of these containers, even at moderately low temperatures.

- Agricultural Products:

PP agricultural products include plant pots, mulch films, and twine.

The low Tg of PP is advantageous for maintaining product shape and toughness in outdoor agricultural applications.

- Consumer Goods:

PP is used in the production of a wide range of consumer goods, including toys, household appliances, kitchenware and containers.

Its low Tg contributes to the durability and stability of these products.

Importance of Tg in large-scale production

PP is in many ways an ideal mass production material. Its properties suit easy and rapid extrusion and molding and its Tg transition is generally completed below ‘normal’ operating conditions for the majority of products. It is also one of the lowest cost polymers and manufactured in very large volumes, making it ideal for single use and enduring use products.

Tg is a crucial parameter in the large-scale production of PP for various reasons; processing temperatures are relatively low; its melt-flow properties are well understood and controlled;

Processing temperatures have significant effects on quality and cost issues;

- Processing temperature control.; Tg defines the appropriate processing temperature for PP during manufacturing. Maintaining the polymer at the correct temperature range is essential to achieve efficient and consistent production.

- Melt flow and moldability; The Tg transition affects its melt flow characteristics and moldability. Understanding Tg allows manufacturers to optimize processing conditions for proper flow, filling, and part formation.

- Energy efficiency; Operating PP at temperatures moderately above its Tg can lead to improved energy efficiency in manufacturing processes. It reduces the viscosity of the polymer, allowing it to flow more easily through equipment, which results in shorter cycle times and reduced energy consumption.

- Part quality and performance; Tg influences the mechanical properties and dimensional stability of PP parts. Controlling Tg within the desired range ensures that manufactured parts meet quality standards and perform as expected in their intended applications.

- Product design and material selection; Knowledge of Tg allows engineers and product designers to select the most suitable PP grade for a specific application.

- Avoiding process issues; Manufacturing with PP at low temperatures results in processing challenges, such as poor flow, high processing pressures, and difficulty in achieving proper mold filling. Exceeding recommended upper temperatures leads to excessive shrinkage and part deformation. Understanding Tg helps prevent these issues. Maintaining tight control over process temperatures during production processes ensures consistency and reproducibility of PP products.

- End-product performance; Tg affects the behavior of PP in its end-use applications. Ensuring that the Tg of the selected grade of PP matches the requirements of the final product is essential for achieving the desired performance and functionality.

Conclusion

Summary of key findings related to polypropylene glass transition temperature

PP exhibits a Tg typically ranging from -20°C to -0°C, with outlier grades at higher temperatures because of chemical cross-linking or additive modifications. It’s a versatile polymer for various applications, because Tg plays a crucial role in determining PP’s material behavior, and the range is both convenient and wide, enabling application-selection. PP’s generally low Tg allows for easy processing and moldability, making it ideal for packaging materials, films, and automotive components.

Understanding Tg helps optimize manufacturing processes, control energy consumption, maintain product quality, and ensure consistent performance in end-use applications. Careful consideration of Tg is essential in product design, material selection, and large-scale PP production for cost-effective and efficient manufacturing processes.

Importance of further research in this area

Continuing research into the Tg of PP remains important for intricate and significant benefits that it regularly delivers in creating new material grades.

- Material optimization

- Energy efficiency

- Advanced processing techniques

- Recycling, biodegradability and sustainability

- Product innovation

- Performance enhancement

- Quality control

- Multifunctional materials

Research into PP material properties – Tg and others – is essential for extending the material families capabilities, improving its sustainability and addressing the increasing demands of various product sectors. This research drives innovation, reduces environmental impact and enhances the performance of PP products.